Top Torque Motors What You Need to Know for Optimal Performance?

In today's industry, torque motors play a critical role in various applications. From robotics to industrial machinery, their performance directly impacts efficiency. According to a recent report by the International Electrotechnical Commission, torque motors have shown a growth potential of 7% annually in demand. Experts agree on their importance. Dr. Emily Hartman, a renowned torque motors specialist, states, "Optimal torque motors enhance precision and reduce operational costs."

The complexity of torque motors also presents challenges. High performance requires careful selection and tuning. Factors such as load characteristics and power ratings must align perfectly. Despite advancements, users often face difficulties when installing or maintaining these systems. Misunderstandings can lead to performance loss and unnecessary expenses.

Embracing the potential of torque motors requires ongoing education and research. Industry professionals must stay updated on trends and technologies. While remarkable progress has been made, there remains room for improvement. Continuous reflection on practices will lead to a better understanding of torque motors' capabilities. Only then can optimal performance be achieved.

Understanding Torque Motors: A Comprehensive Overview

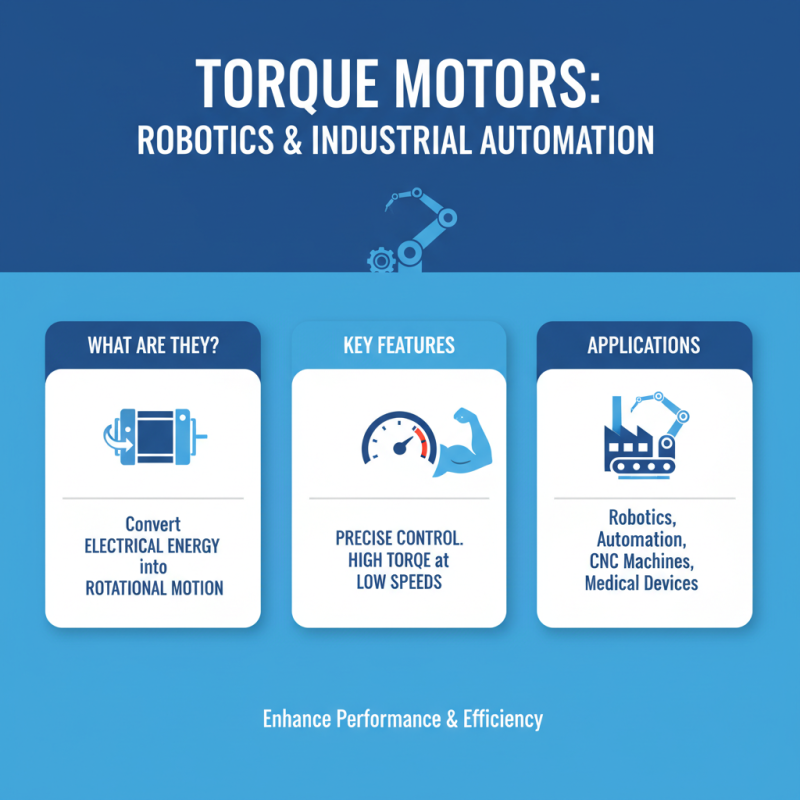

Torque motors are essential for various applications like robotics and industrial automation. These motors convert electrical energy into rotational motion, providing precise control and high torque at low speeds. Understanding how torque motors function can significantly enhance performance in these areas.

One key aspect is the motor's design. Torque motors often have a unique construction that allows for direct drive functionality. They may feature a flat configuration, enabling efficient heat dissipation. This design can sometimes lead to challenges in mechanical integration. Engineers need to account for space limitations and mounting requirements. It requires thoughtful planning and sometimes compromises on design.

Another factor is the application of torque motors. Not all setups benefit equally from their high torque output. In some cases, users might overlook factors like load inertia and system dynamics. This can lead to suboptimal performance. For optimal results, thorough testing and adjustments are crucial. Each application may reveal unforeseen issues, prompting further exploration and refinement for better outcomes.

Types of Torque Motors and Their Applications in Various Industries

Torque motors are versatile and play a crucial role across various industries. They excel in applications where precision and control are essential. You can find these motors in robotics, automation, and manufacturing processes. Each type of torque motor has its specific strengths.

For example, permanent magnet torque motors deliver high torque at low speeds. They’re ideal for applications requiring smooth motion. In contrast, brushless DC torque motors are often used in robotics due to their efficiency and reliability in variable load conditions.

Tips: When choosing a torque motor, consider the speed and load requirements carefully. Test the torque rating to ensure it meets the application's demands. And, remember, not every motor performs best in every situation. Analyze the requirements closely.

Another noteworthy type is the AC torque motor, known for its durability. These motors are commonly used in conveyor systems and heavy machinery. They can handle continuous operations and can be tough under stress.

Tips: Always evaluate the environment where the motor will operate. High temperatures or moisture can cause issues. Regular maintenance is key to optimal performance.

Key Factors Influencing Torque Motor Performance

When it comes to torque motors, several key factors influence their performance. Understanding these factors helps you choose the right motor for your application. One crucial element is the load characteristics. Motors designed for specific loads can perform better. If the motor faces an unexpected load, efficiency may drop. It’s essential to match the motor to the application properly.

Another significant factor is the power supply. Voltage variations can directly affect the torque output. Consistent voltage ensures stable performance. If fluctuations occur, it can lead to overheating or inefficiency. Motor placement also plays a role. Insufficient ventilation may lead to heat buildup, impacting performance negatively. Adequate cooling measures should be implemented to reduce this risk.

Lastly, maintenance is vital. Regular checks can help identify issues early. Often, minor problems can escalate into significant failures. Ignoring these can lead to unexpected downtime. Keeping cables, connections, and components clean is essential. Regular maintenance ensures the torque motor operates optimally and reliably over time.

Top Torque Motors: What You Need to Know for Optimal Performance

| Motor Type | Max Torque (Nm) | Voltage (V) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|

| DC Brushless Motor | 80 | 24 | 90 | 5.5 |

| Stepper Motor | 50 | 12 | 85 | 2.8 |

| AC Induction Motor | 150 | 220 | 92 | 11.0 |

| Synchronous Motor | 100 | 380 | 94 | 8.0 |

| Servo Motor | 10 | 48 | 95 | 1.5 |

Maintenance Practices for Enhancing Torque Motor Longevity

Torque motors are crucial for various applications, from robotics to industrial machinery. Proper maintenance can significantly enhance their longevity and performance. According to a recent industry report, over 30% of torque motor failures are attributed to inadequate maintenance practices. Addressing this issue can drastically reduce costs and downtime.

Regular inspections play a key role in maintenance. Checking for signs of wear can help identify issues before they escalate. Additionally, lubrication is essential. Using the correct lubricant prevents overheating and reduces friction. A study highlights that motors performing routine lubrication saw a 40% increase in lifespan. Operators should not overlook wiring and connections. Corroded contacts can lead to power loss and reduced efficiency.

Incorporating vibration analysis is another method to improve motor longevity. Anomalies in vibration patterns can signal potential problems. Research indicates that monitoring vibration can reduce unexpected failures by up to 25%. Yet, many facilities neglect this practice. Regular training for staff on maintenance best practices can improve awareness. A small investment in education can lead to significant savings in the long run.

Torque Motors Performance Metrics

This chart illustrates the torque output of different torque motors measured in Newton-meters (Nm). Understanding these performance metrics can help you choose the right motor for your application and maintain it effectively for optimal performance.

Future Trends in Torque Motor Technology and Innovation

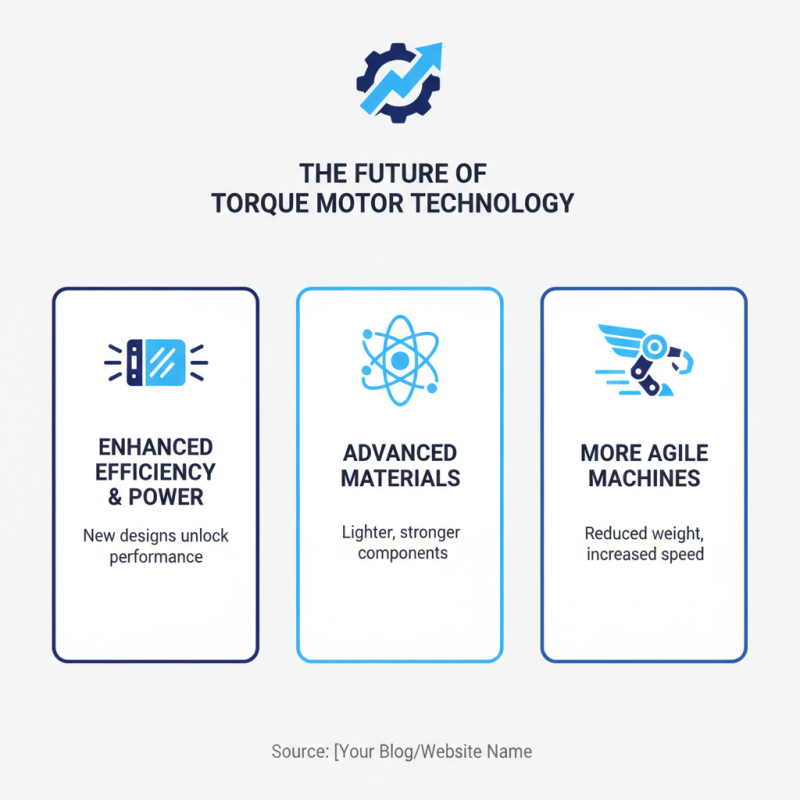

The future of torque motor technology is filled with exciting trends. Engineers are exploring new designs that enhance efficiency and power output. For instance, advancements in materials can drastically reduce weight. Lightweight motors can lead to more agile machines.

Another key trend is the integration of smart technology. Sensors can track performance in real-time. This data enables predictive maintenance, reducing downtime. However, relying on technology raises questions about vulnerability. What happens if a system fails unexpectedly?

Energy efficiency is also a critical focus. Torque motors are moving towards more sustainable designs. This shift can decrease energy consumption. There’s still much work to be done on energy sources. Innovators must continue assessing the balance between power and sustainability in design. These developments challenge traditional norms but are necessary for a greener future.

Related Posts

-

Why Semiconductor Machines Are Essential for the Future of Technology

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs

-

2025 Top 5 Electronics Tools to Enhance Your Productivity and Creativity

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

Unlocking the Mysteries of Motor Control: How Your Brain Powers Movement

-

Exploring the Science Behind Etel Motion and Its Impact on Modern Technology