Top Motion Solutions for Enhanced Efficiency in Modern Industries

In the rapidly evolving landscape of modern industries, efficiency and productivity are paramount. As businesses seek to optimize their operations, the adoption of innovative motion solutions has become increasingly critical. These solutions encompass a wide range of technologies and methodologies designed to streamline processes, reduce waste, and enhance overall performance. By integrating advanced motion solutions into their workflows, companies can not only improve operational effectiveness but also gain a competitive edge in their respective markets.

The essence of motion solutions lies in their ability to transform traditional practices into dynamic, automated, and data-driven operations. From robotics and automated guided vehicles to sophisticated tracking and management systems, these technologies are paving the way for a new era of industrial efficiency. As organizations strive to meet the demands of a fast-paced marketplace, understanding and implementing the right motion solutions is crucial.

In the following sections, we will explore the top motion solutions that are leading the charge in enhancing efficiency across various industries. By examining their applications and benefits, we aim to shed light on how motion solutions can revolutionize the way businesses operate, ultimately driving them towards greater success and sustainability in an increasingly competitive world.

Overview of Motion Solutions in Modern Industries

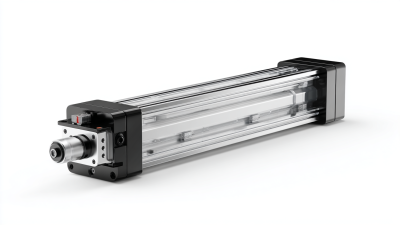

In contemporary industries, motion solutions play a pivotal role in enhancing operational efficiency and productivity. At the core of modern manufacturing, logistics, and automation, these solutions include technologies such as servo motors, pneumatic actuators, and linear guides that together facilitate precise movement and control of machinery. As companies strive to optimize their processes, the adoption of advanced motion solutions can significantly reduce lead times, improve accuracy, and minimize waste.

Moreover, the integration of smart technologies into motion systems has transformed traditional practices. The implementation of robotics, along with real-time data analytics, provides businesses with insights that enhance decision-making and operational responsiveness. For instance, motion-controlled systems now often incorporate sensors for monitoring performance, thereby enabling predictive maintenance and reducing downtime. This technological advancement not only boosts efficiency but also contributes to sustainability by minimizing energy consumption and resource usage in various industrial applications.

Top Motion Solutions for Enhanced Efficiency in Modern Industries

Key Technologies Driving Motion Efficiency

In modern industries, enhancing motion efficiency is critical for boosting productivity and optimizing operations. Key technologies driving this efficiency encompass advanced automation, precise control systems, and innovative motion sensors. These technologies work in tandem to streamline workflows, reduce energy consumption, and improve the overall reliability of industrial processes.

Automation, powered by digital tools and robotics, allows for the seamless execution of repetitive tasks while minimizing human intervention. This not only enhances speed but also ensures consistent quality in production. Additionally, precise control systems enable real-time adjustments and monitoring of machinery, allowing industries to adapt swiftly to variations in demand or operational conditions.

Meanwhile, innovative motion sensors provide valuable data that contributes to predictive maintenance strategies, ensuring equipment runs smoothly and reducing unplanned downtime. Together, these technologies pave the way for a more efficient and responsive industrial landscape.

Applications of Motion Solutions Across Various Sectors

Motion solutions play a crucial role in enhancing operational efficiencies across various industries, from manufacturing to healthcare. According to a report by the International Federation of Robotics, the global market for industrial robotics is projected to reach $70 billion by 2025, highlighting the rapid adoption of advanced motion technologies. These solutions not only streamline production processes but also minimize operational costs, allowing businesses to achieve higher throughput with fewer resources.

In the automotive sector, for instance, automated motion systems have led to a 30% increase in productivity, as stated in a recent McKinsey report. By automating assembly lines with motion control systems, manufacturers can improve accuracy and reduce the time taken to produce vehicles. Furthermore, the integration of motion solutions in logistics and supply chain management has become indispensable, with a market growth prediction of 16% annually, driven by the demand for real-time tracking and robotic automation. These applications demonstrate how motion technologies are transforming industry operations, promoting greater efficiency and sustainability across the board.

Top Motion Solutions for Enhanced Efficiency in Modern Industries

| Industry Sector | Motion Solution Type | Application | Efficiency Improvement (%) |

|---|---|---|---|

| Manufacturing | Servo Motors | Automated Assembly Lines | 20% |

| Logistics | Robotic Arms | Material Handling | 30% |

| Automotive | Linear Actuators | Adaptive Cruise Control | 15% |

| Food Processing | Belt Conveyors | Packaging and Sorting | 25% |

| Textiles | Step Motors | Precision Weaving | 18% |

| Pharmaceuticals | Pneumatic Systems | Automated Dosing | 22% |

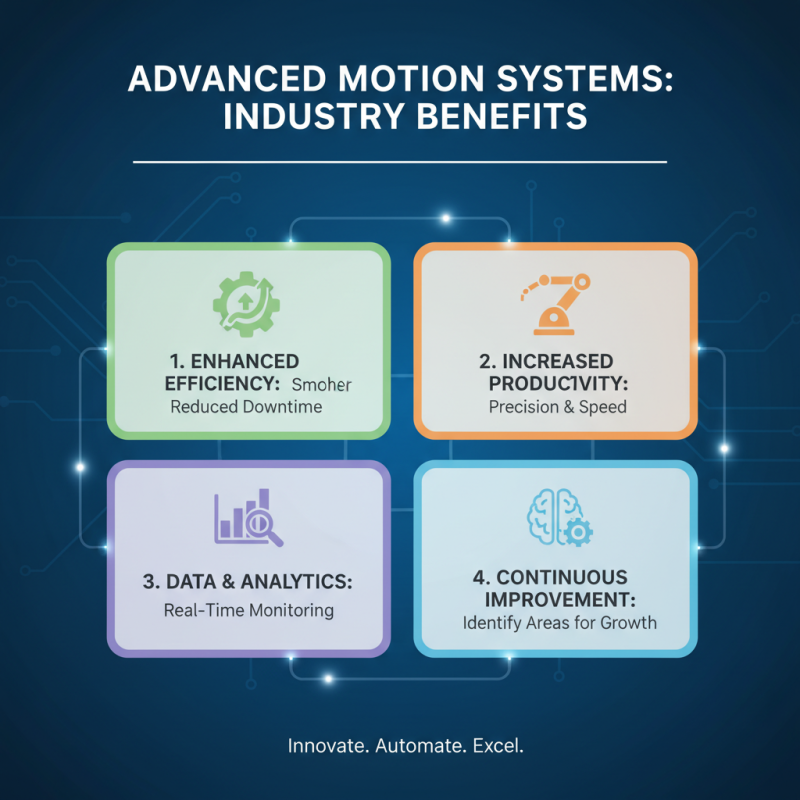

Benefits of Implementing Advanced Motion Systems

The implementation of advanced motion systems in modern industries brings numerous benefits that significantly enhance operational efficiency. By integrating these sophisticated systems into various processes, companies can achieve smoother workflows and reduce downtime. Enhanced precision in movement enables higher productivity levels, as tasks are completed with greater speed and accuracy. Furthermore, advanced motion solutions provide real-time data and analytics, allowing businesses to monitor performance and identify areas for improvement.

Tips for successful implementation include assessing current processes to determine where motion systems can be integrated most effectively. It’s crucial to invest in training staff to ensure they understand the new technologies and can utilize them to their full potential. Additionally, regular maintenance and updates of motion systems can prevent unexpected disruptions and keep operations running smoothly.

Another key advantage of advanced motion systems is their ability to optimize resource use. By automating repetitive tasks, companies can allocate human resources to more complex functions that require critical thinking and creativity. This shift not only improves job satisfaction among employees but also contributes to overall business growth. Emphasizing a culture of continuous improvement and adaptation will allow companies to remain competitive in a rapidly evolving industrial landscape.

Future Trends in Motion Solutions and Industry Implications

As industries evolve, the integration of advanced motion solutions is set to significantly reshape operational efficiency. According to a report by MarketsandMarkets, the global motion control market is projected to reach $21.12 billion by 2026, growing at a CAGR of 7.2% from 2021. This growth is driven by the increasing demand for automated processes and the need for precision in various applications, from manufacturing to logistics. As organizations adopt smart technologies, such as artificial intelligence and IoT, the role of motion solutions becomes increasingly critical in enhancing productivity and reducing operational costs.

Future trends in motion solutions indicate a shift towards more adaptive and intelligent systems. The implementation of machine learning algorithms in motion control facilitates predictive maintenance, reducing downtime and maintenance costs by as much as 30% according to a recent Deloitte study. Moreover, advancements in robotics and automation technologies are pushing the boundaries of what is possible in motion control, enabling more intricate operations that enhance throughput while ensuring safety and accuracy. As these technologies continue to mature, industries that leverage them are likely to gain a competitive edge, resulting in a ripple effect of innovation across the market.

Related Posts

-

Top 10 Motion Solutions for Streamlined Business Operations

-

The Future of Automation with Etel Linear Motors What You Need to Know

-

10 Essential Tips for Understanding Motors and Control Systems Effectively

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

2025 Top 5 Electronics Tools to Enhance Your Productivity and Creativity