Top 10 Linear Motor Controllers for Optimal Performance in 2023

In the ever-evolving landscape of industrial automation, the demand for precise motion control has led to significant advancements in technology. Central to these developments is the linear motor controller, a crucial component responsible for ensuring optimal performance in various applications ranging from robotics to semiconductor manufacturing. As industries strive for higher efficiency and accuracy, selecting the right linear motor controller becomes paramount.

In 2023, professionals and engineers are presented with an extensive range of options that promise to enhance operational effectiveness. The importance of understanding the specifications, features, and capabilities of these controllers cannot be overstated, as they directly impact the performance of linear motors. This comprehensive guide aims to spotlight the top 10 linear motor controllers currently available, highlighting their unique attributes that cater to the diverse needs of modern manufacturing processes. By delving into these options, users can make informed decisions that align with their technical requirements and performance goals, ultimately leading to improved productivity and innovation in their respective fields.

Overview of Linear Motors and Their Applications in 2023

Linear motors are revolutionizing various industries in 2023, primarily due to their ability to provide direct linear motion without the need for mechanical components such as gears and belts. This technology is extensively utilized in applications ranging from industrial automation to precision machining and transportation systems. According to a recent report from the International Federation of Robotics, the global market for linear motors is expected to grow at a CAGR of approximately 7.5% from 2023 to 2028, driven by the increasing demand for high-speed, high-precision applications.

The versatility of linear motors extends to sectors such as medical devices, semiconductor manufacturing, and material handling. For instance, in the semiconductor industry, linear motors facilitate the rapid and precise movement required for wafer processing, dramatically enhancing efficiency and yield. A study published by Market Research Future highlights that the adoption of linear motors in medical technology has led to significant improvements in the performance of diagnostic equipment and robotic surgical systems, thereby enhancing patient outcomes and operational efficiency. As industries continue to innovate, the integration of linear motors into automated systems is poised to play a crucial role in meeting the growing demand for speed and accuracy.

Key Features to Look for in Linear Motor Controllers

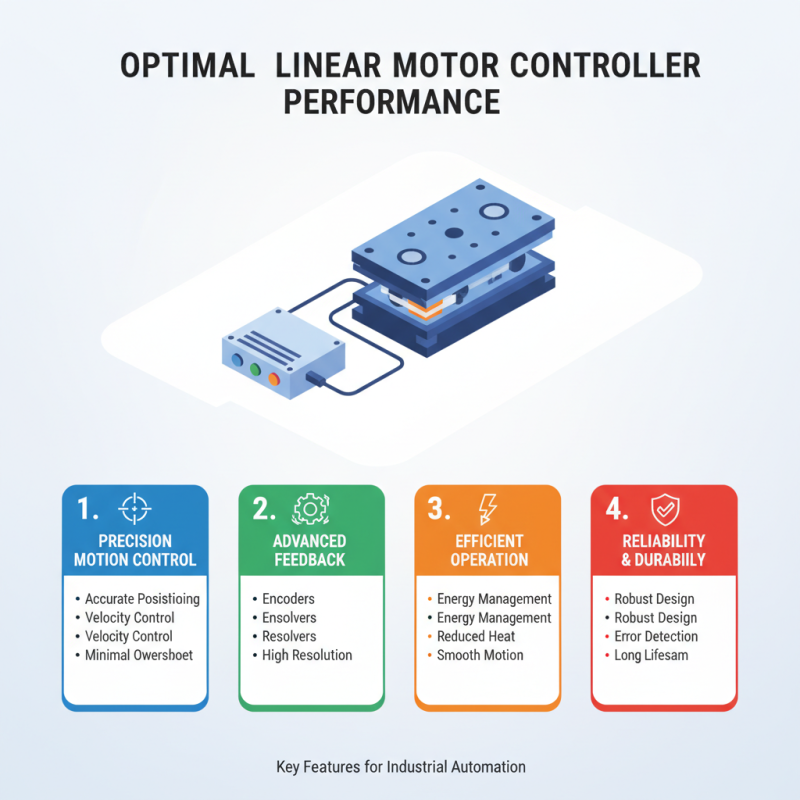

When evaluating linear motor controllers for optimal performance, several key features should be prioritized to ensure efficient operation and reliability. First and foremost, precision in motion control is essential. Advanced feedback mechanisms, such as encoders and resolvers, play a crucial role in delivering accurate positioning and velocity control. The ability to achieve high resolution and minimal overshoot is particularly important in applications where precision is paramount.

Additionally, adaptability and versatility are vital characteristics of a top-tier linear motor controller. The ideal controller should support a range of communication protocols and automation standards, enabling seamless integration into existing systems. Features like programmable parameters allow users to tailor the controller's behavior according to specific application requirements, enhancing both responsiveness and performance. Furthermore, robust thermal management systems are necessary to maintain optimal operating temperatures, ensuring the longevity and reliability of the controller during extended use.

Another critical aspect to consider is the user interface and ease of programming. Intuitive software tools that facilitate quick setup and troubleshooting can significantly reduce downtime and improve overall productivity. Comprehensive diagnostic features can help operators monitor performance metrics in real-time, allowing for proactive maintenance and minimizing the risk of unexpected failures. By focusing on these essential features, users can select a linear motor controller that not only meets their immediate needs but also provides the flexibility to adapt to future challenges.

Top 10 Linear Motor Controllers for Enhanced Performance

In the rapidly evolving field of automation and robotics, selecting the right linear motor controller is crucial for enhancing performance. These controllers play a pivotal role in driving linear motors, offering precise movement and improved efficiency in applications ranging from industrial machinery to medical devices. Advanced control algorithms and feedback mechanisms are essential features that ensure optimal performance, catering to the ever-increasing demands of precision and speed in modern systems.

Moreover, the integration of digital interfaces and communication protocols has revolutionized how linear motor controllers interact with other system components. Enhanced diagnostics and real-time monitoring capabilities provide users with valuable insights into system performance, allowing for proactive maintenance and minimizing downtime. As industries focus on increasing productivity and reducing operational costs, investing in advanced linear motor controllers becomes imperative for achieving superior performance and reliability in applications across various sectors.

Comparison of the Best Linear Motor Controllers on the Market

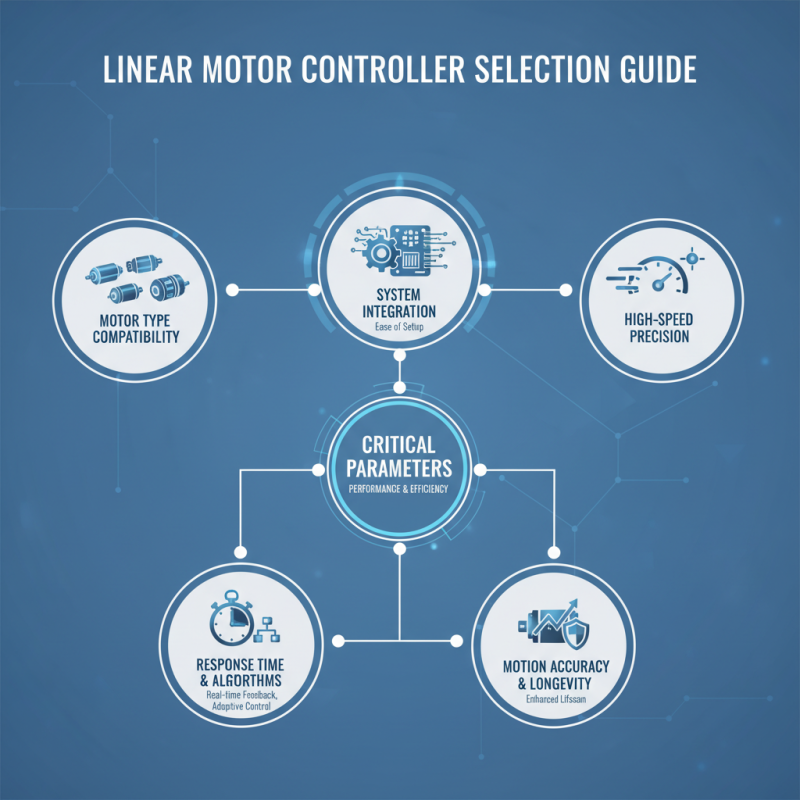

When selecting a linear motor controller, one must consider the critical parameters that define performance and efficiency. Key factors include compatibility with various linear motor types, ease of integration into existing systems, and the ability to manage high-speed operations with precision. The response time and control algorithms implemented in these controllers significantly affect their overall performance, with advanced models offering features like real-time feedback and adaptive control capabilities. This enhances not only the accuracy of motion but also the longevity of the linear motors themselves.

Additionally, the robustness and reliability of the controller under different operating conditions are paramount. Factors such as thermal management, protection against electrical noise, and responsiveness to load changes play a crucial role in determining the suitability of a controller for specific applications. In 2023, the market offers a diverse range of linear motor controllers, each designed to meet different needs in industries like automation, robotics, and manufacturing. Detailed comparisons of their features, such as power handling, ease of programming, and user interface design, will help users make informed choices tailored to their project requirements.

Future Trends in Linear Motor Technology and Control Systems

As linear motor technology continues to evolve, several future trends are emerging in control systems that are set to enhance performance and efficiency. One significant trend is the growing integration of artificial intelligence into linear motor controllers. By leveraging AI algorithms, these systems can optimize operational parameters in real-time, thereby improving responsiveness and energy efficiency. This shift not only enhances precision but also allows for predictive maintenance, reducing downtime and operational costs.

Another key trend is the miniaturization of control systems, enabling them to be more compact and versatile. This development provides designers with greater flexibility when integrating linear motors into various applications, from robotics to automation in manufacturing. As systems become smaller and more powerful, they open doors to innovative uses in spaces previously thought unsuitable for linear motors.

**Tip:** When selecting a linear motor controller, consider the adaptability of the system to future technologies like AI. Choosing controllers that support firmware updates or integration with new smart technologies can ensure longevity and scalability in your operations.

Additionally, advancements in communication protocols are paving the way for more connected systems. The use of IoT (Internet of Things) in linear motor applications facilitates seamless communication between devices, allowing for better data collection and analysis. This connectivity can lead to enhanced monitoring capabilities and better overall system performance.

**Tip:** Look for controllers that offer robust communication features, as these will not only improve current operational efficiencies but also position your system well for future advancements in automation and control technology.

Top 10 Linear Motor Controllers for Optimal Performance in 2023

| Rank | Model | Max Current (A) | Voltage Range (V) | Control Type | Communication Protocols | Key Features |

|---|---|---|---|---|---|---|

| 1 | Model A | 30 | 24-60 | PID | CAN, EtherCAT | High precision, compact size |

| 2 | Model B | 25 | 18-48 | PID | RS-232, Profibus | Robust design, easy integration |

| 3 | Model C | 40 | 20-80 | Fuzzy Logic | USB, MQTT | Adaptive control, high dynamics |

| 4 | Model D | 35 | 15-45 | PID | Ethernet, CANopen | Flexible configuration, reliable |

| 5 | Model E | 50 | 30-120 | Direct Control | Modbus, CAN | High torque, low latency |

| 6 | Model F | 45 | 10-50 | PID | Serial, I2C | Compact, energy-efficient |

| 7 | Model G | 60 | 36-72 | PMSM | EtherCAT, RS-485 | Dynamic performance, versatile |

| 8 | Model H | 20 | 12-36 | PID | CANopen, LIN | Low power consumption, user-friendly |

| 9 | Model I | 55 | 25-100 | BLDC | Analog, Digital | Precision positioning, compact |

| 10 | Model J | 15 | 5-30 | Open-loop | I2C, SPI | Simple setup, cost-effective |

Related Posts

-

10 Best Etel Motors Models You Need to Know for 2024

-

Unlocking the Future Engaging in a Rewarding Semiconductor Career Path

-

Exploring the Future of Semiconductor Career Opportunities in a Rapidly Evolving Industry

-

2025 Top 5 Electronics Tools to Enhance Your Productivity and Creativity

-

Unlocking the Future: How Semiconductor Manufacturing is Powering Tomorrow's Technologies

-

2025 Guide: How to Improve Motor Control for Better Performance