Essential Tips for Choosing the Right Semiconductor Machine for Your Needs

In the rapidly evolving landscape of technology, selecting the right semiconductor machine is crucial for manufacturers aiming to enhance their production processes. As the backbone of modern electronic devices, semiconductor machines play an essential role in the fabrication and assembly of microchips and other vital components. The complexity and precision required in this domain make it imperative for businesses to understand the factors influencing their machine selection.

Whether you are an established player in the semiconductor industry or a newcomer exploring the potential of this field, knowing how to choose the right equipment can greatly affect your operational efficiency and product quality. This guide aims to provide insightful tips to navigate the complex array of options available in the market, helping you identify the specifications and features that align with your specific needs.

By taking into consideration aspects such as machine reliability, scalability, and technological advancements, you can make informed decisions that not only meet your current requirements but also accommodate future developments. Emphasizing the importance of strategic choice in semiconductor machinery will ensure that your production capabilities remain competitive and profitable in this dynamic industry.

Understanding Different Types of Semiconductor Machines Available

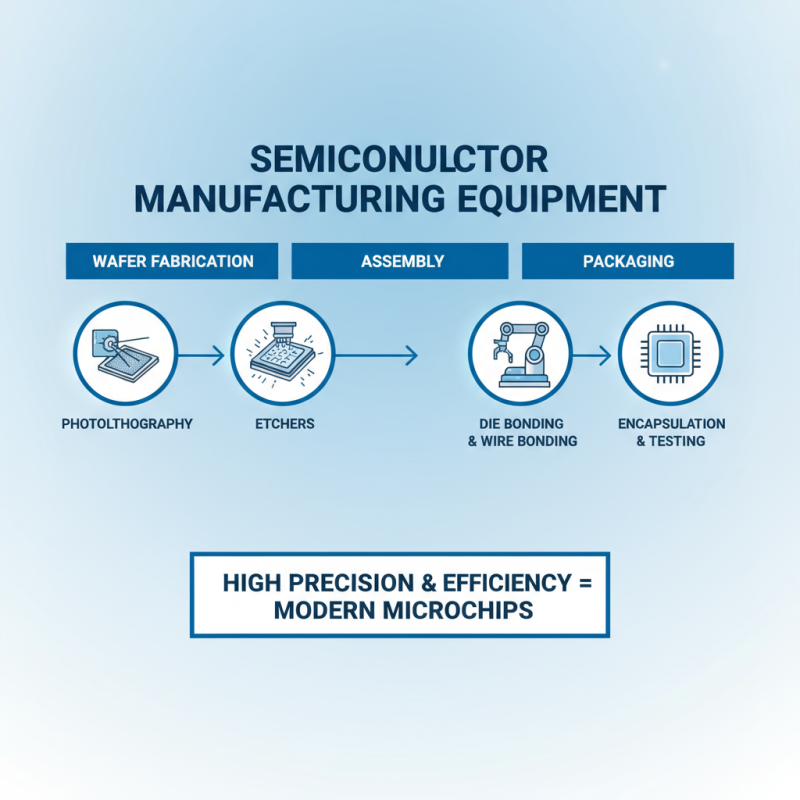

When selecting a semiconductor machine, understanding the various types available is crucial to meet your specific needs. Semiconductor machines can be broadly categorized into equipment used in wafer fabrication, assembly, and packaging. Wafer fabrication tools, such as photolithography machines, etchers, and ion implanters, are essential for creating integrated circuits on silicon wafers. These machines are designed to ensure high precision and efficiency, which are critical in producing modern microchips.

On the other hand, assembly and packaging machines focus on the final stages of semiconductor device production. This includes wire bonders, die attachers, and mold machines that help in encapsulating the chips and connecting them to their respective substrates. Each machine serves a distinct purpose and varies in complexity, from fully automated systems to semi-automated ones. Understanding these different types of machines and their functions helps in determining the right specifications needed for a production line, enabling manufacturers to enhance productivity and achieve desired outcomes efficiently.

Key Specifications to Consider When Selecting Semiconductor Equipment

When selecting semiconductor equipment, key specifications play a crucial role in ensuring that the machinery meets your production needs. One of the foremost parameters to consider is throughput, or the rate at which the equipment can process semiconductors. According to a recent market analysis by SEMI, the global semiconductor manufacturing equipment market is projected to grow significantly, with an emphasis on high-throughput systems that can enhance productivity by up to 30% compared to traditional machines. This increase in productivity is crucial as demand for semiconductors continues to escalate amid advances in technology.

Another important specification is precision and accuracy. The semiconductor industry requires equipment capable of achieving tight tolerances to produce chips that operate reliably in modern applications. A 2022 report by Statista highlighted that the rise of devices such as artificial intelligence and Internet of Things devices necessitate advancements in manufacturing precision, with tolerances shrinking to less than 10 nanometers in some cases. Therefore, selecting machines that offer high levels of accuracy can significantly affect the quality and performance of the chips produced.

Efficiency in power consumption is also a vital consideration. As energy costs rise, semiconductor manufacturers are increasingly focused on purchasing equipment that not only delivers performance but also optimizes energy usage. A study published by IC Insights found that energy-efficient machines can reduce power costs by up to 20%, contributing to lower operational expenses and a smaller carbon footprint. As sustainability becomes a key concern in the industry, selecting equipment that balances performance with environmental responsibility can set manufacturers apart in a competitive market.

Evaluating Your Production Volume and Its Impact on Machine Choice

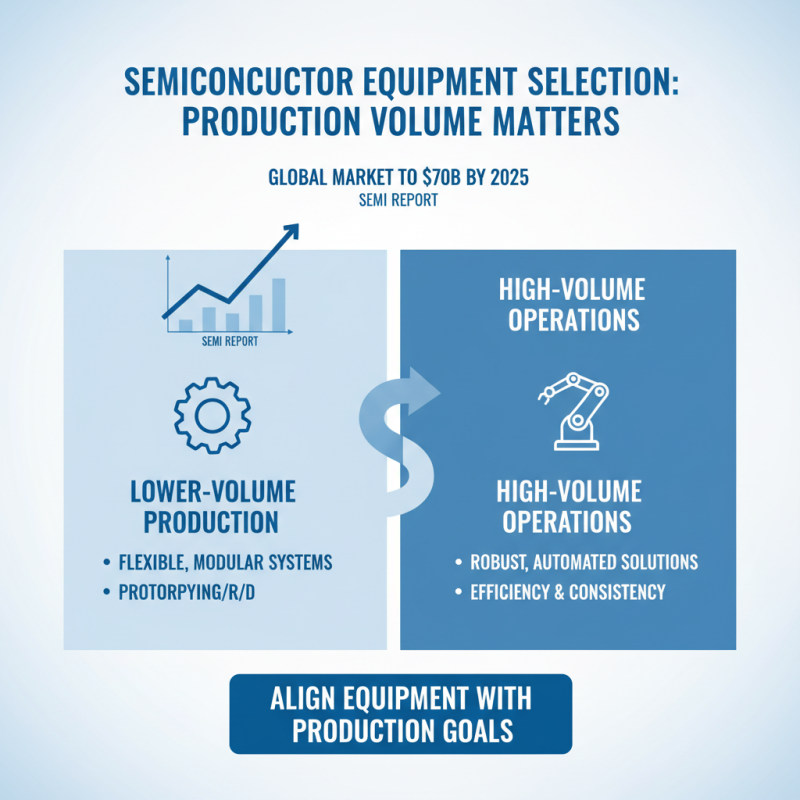

When selecting a semiconductor machine, evaluating your production volume is crucial, as it directly influences the type of equipment that will best meet your needs. According to a report by the Semiconductor Equipment and Materials International (SEMI), the global semiconductor manufacturing equipment market is expected to reach $70 billion by 2025, a significant increase driven by the rise in demand for electronic devices. This underscores the importance of aligning your machine choice with your production objectives. For instance, lower-volume production might benefit from flexible, modular systems, while high-volume operations require robust, automated solutions that maintain efficiency and product consistency.

In considering production volume, it's also essential to analyze trends in the semiconductor industry. Data from Gartner indicates that semiconductor sales are projected to grow by 12.5% annually, highlighting the necessity for machines that can scale operations effectively. For manufacturers anticipating rapid scale-up, investing in high-throughput machines can improve yield and reduce time-to-market. Additionally, understanding the specific requirements for various production scales can prevent costly mistakes and ensure manufacturers remain competitive. By accurately assessing production needs, companies can strategically choose machines that not only meet current demands but are also future-proof against the evolving landscape of semiconductor fabrication.

Budgeting for Your Semiconductor Machine Acquisition and Maintenance

When budgeting for your semiconductor machine acquisition and maintenance, it is essential to start with a comprehensive analysis of your operational needs. This involves assessing the specific processes and technology that your semiconductor production requires, ensuring that you select machinery that aligns with those demands. The initial cost of the machine is just one part of the equation; you should also factor in ongoing costs such as maintenance, consumables, and potential upgrades. Conducting a thorough cost-benefit analysis will help in identifying not only the upfront investment but also the long-term financial implications of ownership.

Next, it’s crucial to consider the financing options available for your semiconductor machinery. Many businesses may opt for leasing instead of purchasing outright, which can significantly reduce initial expenditures. Additionally, setting aside a budget for regular maintenance and unexpected repairs will safeguard against disruption in production. Account for training costs as well, as proper operation of sophisticated semiconductor machines can require specialized knowledge. By evaluating all these aspects, your budgeting process will provide a clearer picture of the total investment and assist you in making an informed decision that supports your long-term operational goals.

Assessing the Future Scalability of Your Semiconductor Manufacturing Needs

When selecting a semiconductor machine, one crucial aspect to consider is the future scalability of your manufacturing needs. The semiconductor industry is characterized by rapid technological advancements and fluctuating market demands. As such, choosing equipment that can adapt to future requirements is essential for long-term success. Assess how well potential machines can accommodate new processes, increased production volumes, and the integration of advanced technologies. Evaluating these factors helps ensure that your investment remains relevant as your production goals evolve.

Additionally, it's important to look beyond the immediate capabilities of the machinery. Consider the modularity and upgradeability of the equipment. Machines that allow for easy upgrades and modifications can significantly extend their lifespan and adapt to industry changes. This flexibility can not only help you meet current production targets but also adapt to emerging technologies like AI integrations or improved fabrication techniques. Careful assessment of these scalability features will enable you to make informed decisions that align with your growth strategy in the competitive semiconductor landscape.

Related Posts

-

Unlocking the Future: How Semiconductor Manufacturing is Powering Tomorrow's Technologies

-

Understanding the Semiconductor Process and Its Impact on Technology Development

-

Unlocking the Future of Therapy: How Etel Motion Transforms Movement Rehabilitation

-

The Future of Automation with Etel Linear Motors What You Need to Know

-

2025 Top 10 Innovations in Motors and Control Systems You Must Know

-

Exploring the Science Behind Etel Motion and Its Impact on Modern Technology