Why Semiconductor Machines Are Essential for the Future of Technology

As the backbone of modern technology, semiconductor machines play an increasingly pivotal role in shaping the future of various industries. These complex devices are integral in the manufacturing of semiconductors, which are essential components in everything from smartphones and computers to advanced artificial intelligence systems. The demand for faster, more efficient processing power drives innovation in semiconductor machines, making them a key focus for technological advancement.

In today’s fast-paced digital world, the significance of semiconductor machines cannot be overstated. They not only facilitate the production of smaller and more powerful chips but also contribute to achieving breakthroughs in fields such as telecommunications, automotive engineering, and renewable energy. As we enter an era characterized by rapid technological changes, the efficiency and precision offered by semiconductor machines will be crucial for staying ahead of the curve and meeting the evolving needs of consumers and businesses alike.

Moreover, the ongoing advancements in semiconductor technology are set to revolutionize the way we interact with our environment, enabling the development of smarter, more connected devices. As reliance on technology continues to grow, the importance of semiconductor machines will only increase, solidifying their role as foundational tools for propelling society into the future of innovation.

The Role of Semiconductor Machines in Modern Electronics Manufacturing

Semiconductor machines play a pivotal role in modern electronics manufacturing, acting as the backbone of the entire production process. These machines are designed to create intricate circuits that form the essence of electronic devices, ranging from smartphones to advanced computing systems. By enabling precision in layering, etching, and doping of semiconductor materials, they ensure that devices can operate at higher speeds and greater efficiencies. The complexity of modern electronics demands highly sophisticated machinery that can produce components with nanometer-scale features, making semiconductor machines indispensable for manufacturers looking to stay competitive in a fast-evolving technology landscape.

Furthermore, the integration of automation and artificial intelligence in semiconductor manufacturing processes has dramatically enhanced productivity and quality control. These advanced machines not only streamline production but also minimize waste and reduce the potential for defects. The evolving design requirements of newer technologies, such as artificial intelligence and 5G networks, necessitate ever-more sophisticated semiconductor solutions. As industries ramp up their demand for cutting-edge electronics, the advancement of semiconductor machines becomes a critical factor in fulfilling these needs, thus reinforcing their essential role in the framework of modern electronics manufacturing.

Importance of Semiconductor Machines in Electronics Manufacturing

The chart above illustrates the estimated investment in various semiconductor machines crucial for modern electronics manufacturing. As technology advances, the importance of machines such as photolithography, etching, deposition, inspection, and packaging continues to grow, reflecting the essential role they play in driving innovation and efficiency in the semiconductor industry.

Key Technologies Behind Semiconductor Machine Functionality

Semiconductor machines play a pivotal role in the modern technological landscape, driven by various key technologies that enhance their functionality and efficiency. At the heart of these machines are lithography systems, which utilize advanced optics to project circuit patterns onto silicon wafers. This precision is crucial for creating the intricate microstructures required in semiconductor devices, enabling the production of smaller and more powerful chips. The development of extreme ultraviolet (EUV) lithography has taken this to new heights, allowing for the manipulation of features at the nanoscale, pushing the boundaries of Moore's Law and enhancing the performance of integrated circuits.

Semiconductor machines play a pivotal role in the modern technological landscape, driven by various key technologies that enhance their functionality and efficiency. At the heart of these machines are lithography systems, which utilize advanced optics to project circuit patterns onto silicon wafers. This precision is crucial for creating the intricate microstructures required in semiconductor devices, enabling the production of smaller and more powerful chips. The development of extreme ultraviolet (EUV) lithography has taken this to new heights, allowing for the manipulation of features at the nanoscale, pushing the boundaries of Moore's Law and enhancing the performance of integrated circuits.

Another essential technology is the deposition and etching processes, which involve the layering and sculpting of materials to form electronic components. Techniques such as atomic layer deposition (ALD) and reactive ion etching (RIE) enable manufacturers to achieve high levels of control over the material properties and dimensions. These processes are fundamental for producing transistors, capacitors, and other vital elements within a chip, leading to improved performance and reduced power consumption in electronics. As the demand for smaller, faster, and more efficient devices continues to rise, advancements in these core semiconductor technologies will remain crucial for fueling innovation across various sectors, from consumer electronics to artificial intelligence.

The Impact of Semiconductor Machines on Global Technology Advancement

Semiconductor machines play a pivotal role in shaping the future of global technology by driving advancements across a multitude of sectors. Their ability to fabricate microchips has revolutionized industries such as computing, telecommunications, and consumer electronics. The precision and efficiency with which these machines operate enable the production of increasingly complex chips that power everything from smartphones to artificial intelligence applications. As technology continues to evolve, the demand for enhanced performance and miniaturization places semiconductor machines at the heart of innovation, making them indispensable to the momentum of technological growth.

Moreover, the impact of semiconductor machines extends beyond individual products and companies; they are fundamental to the framework of global connectivity and economic development. As nations strive for technological self-reliance, investments in semiconductor manufacturing and its associated machinery are seen as critical to maintaining competitive advantage. This trend fosters international collaborations and drives research into advanced materials and processes, ultimately leading to breakthroughs that can address global challenges such as energy efficiency and sustainability. In this context, semiconductor machines are not just tools for production; they are catalysts for a more interconnected and technologically advanced future.

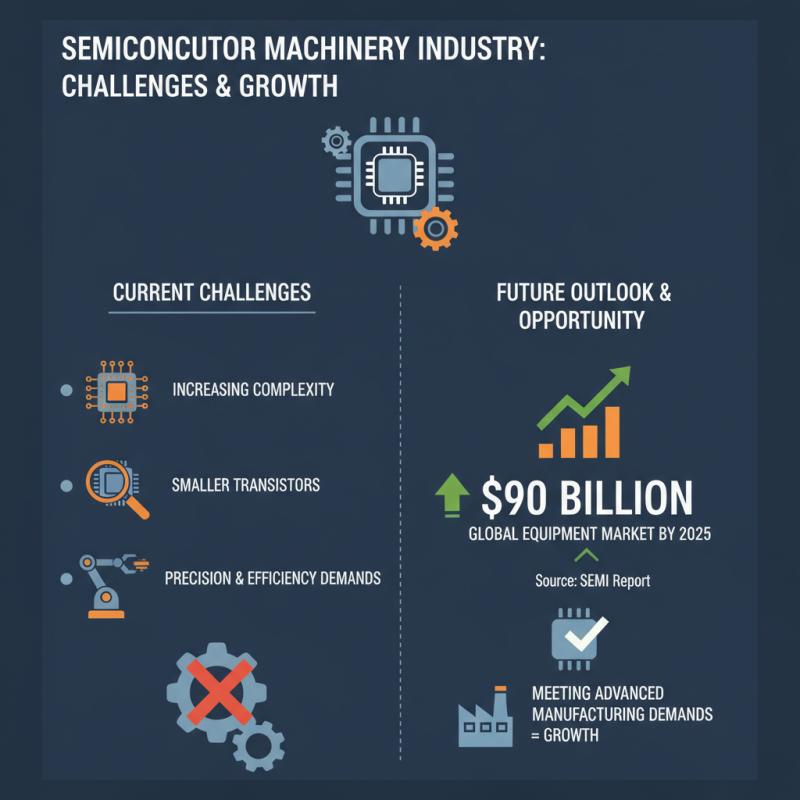

Challenges Facing the Semiconductor Machinery Industry Today

The semiconductor machinery industry is currently navigating a landscape fraught with challenges that threaten its growth and innovation potential. One of the most pressing issues is the increasing complexity of semiconductor manufacturing processes. As transistors continue to shrink in size, the machinery used must evolve to meet stringent precision and efficiency requirements. According to a report by the Semiconductor Equipment and Materials International (SEMI), the global semiconductor equipment market is projected to grow to $90 billion by 2025, highlighting the need for advanced machinery; however, the inability to meet these advanced manufacturing demands could result in bottlenecks that stifle growth.

Moreover, supply chain disruptions have become a critical concern, exacerbated by geopolitical tensions and the pandemic’s aftereffects. The World Semiconductor Trade Statistics (WSTS) has noted that the semiconductor supply chain remains vulnerable, with an estimated 20% of the production capacity failing to meet current demands. This gap necessitates a re-evaluation of supply chain strategies to ensure that semiconductor machinery is readily available, thus supporting the overall industry’s resilience. As manufacturers strive to innovate within this dynamic environment, addressing these challenges will be crucial for sustaining momentum in the semiconductor sector and ensuring its role as a cornerstone of future technological advancements.

Future Innovations and Trends in Semiconductor Machine Technology

The future of technology is intricately linked to advancements in semiconductor machine technology, which plays a pivotal role in driving innovations across various sectors. As the demand for miniaturization and efficiency grows, semiconductor machines are evolving to meet these challenges. Innovations such as extreme ultraviolet (EUV) lithography allow for the production of smaller, more powerful chips. These machines are not just improving performance; they’re enabling entirely new applications, from artificial intelligence to quantum computing, which were previously thought to be unattainable.

Additionally, trends in semiconductor manufacturing point towards increasing automation and the use of artificial intelligence to enhance production processes. Smart factories are emerging, where data analytics and machine learning contribute to real-time decision making and optimization of resource allocation. This increased efficiency not only reduces costs but also accelerates the pace of innovation in consumer electronics, telecommunications, and automotive industries. As these technologies continue to mature, the role of semiconductor machinery will be fundamental in shaping the next generation of technological breakthroughs, ensuring that industries can keep pace with the ever-evolving digital landscape.

Related Posts

-

Top 5 Benefits of Using Etel Motion for Your Fitness Journey

-

Understanding the Basics of Motor Control: How Your Brain Coordinates Movement

-

Unlocking the Future: How Motors and Control Systems Propel Innovation in Technology

-

Unlocking the Future: How Semiconductor Manufacturing is Powering Tomorrow's Technologies

-

Exploring the Future of Electric Vehicles with Etel Motors and Industry Trends in Sustainable Transportation

-

What is the Best Electronics Tools for Every DIY Project