2025 How to Select the Right Motors and Control Systems for Your Project

In the rapidly evolving landscape of engineering and technology, selecting the appropriate motors and control systems is pivotal for the success of any project. According to a recent report by the International Electromechanical Association, the global electric motor market is projected to reach approximately $160 billion by 2025, reflecting a significant annual growth rate driven by increasing automation across various industries. This underscores the critical role that motors and control technologies play in enhancing operational efficiency and productivity.

Expert insights emphasize the importance of making informed decisions in this domain. Dr. Emily Carter, a renowned authority in motors and control systems, asserts, "The right choice of motors and control systems can dramatically influence the performance and reliability of your entire project." This statement resonates with engineers who understand that the integration of advanced motor technologies, coupled with sophisticated control mechanisms, can lead to substantial improvements in system responsiveness and energy efficiency.

As we delve into the intricacies of how to select the right motors and control systems for your specific project, it becomes essential to consider not only technical specifications but also evolving industry trends and best practices. By strategically navigating these considerations, project leaders can leverage motors and control innovations to drive forward their technological initiatives.

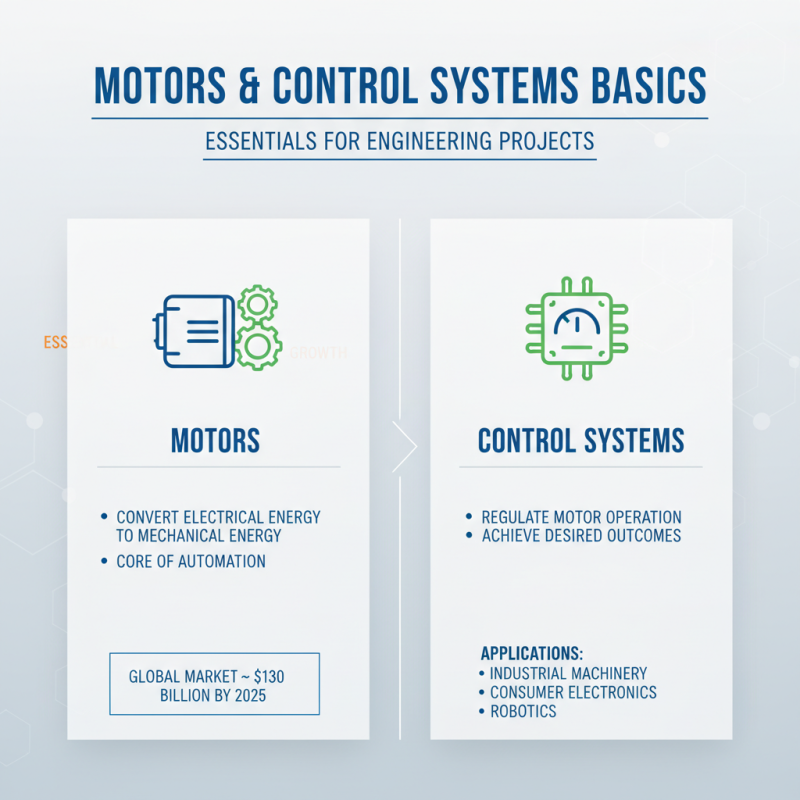

Understanding the Basics of Motors and Control Systems

Understanding the basics of motors and control systems is essential when selecting the right components for any engineering project. At the heart of most automation processes, motors convert electrical energy into mechanical energy, while control systems regulate their operation to achieve desired outcomes. In recent years, there has been significant growth in the global electric motor market, projected to reach approximately $130 billion by 2025, according to industry reports. This growth highlights the increasing reliance on efficient and reliable motors in various applications, from industrial machinery to consumer electronics.

When choosing a motor, engineers must consider factors such as torque, speed, and power requirements. For instance, brushless DC motors have gained popularity due to their high efficiency and low maintenance needs, offering efficiencies of up to 90%. On the other hand, control systems, such as programmable logic controllers (PLCs) and digital signal processors (DSPs), play a pivotal role in optimizing motor performance. According to a study by MarketsandMarkets, the global PLC market is expected to grow at a CAGR of 6.88%, indicating a rising demand for sophisticated control solutions that enhance automation capabilities. Understanding these fundamentals allows engineers to create more effective, reliable, and scalable automation solutions tailored to their specific projects.

Identifying Project Requirements for Motor Selection

When selecting the right motors and control systems for your project, it's essential to first identify the specific requirements. This includes understanding the application’s operational needs, such as speed, torque, and load conditions. Consider the environment in which the motor will operate—factors like temperature, humidity, and exposure to dust can significantly affect performance.

Moreover, assessing the power source available for the motor is critical; it determines whether to use AC, DC, or stepper motors based on energy efficiency and control capabilities.

Tips: Always start by outlining the specific tasks the motor will perform. This will guide you in defining the necessary specifications such as rotational speed and power ratings. Additionally, consult with engineering experts or utilize simulation software to visualize how different motors will interact within the overall system design before making a decision.

Another essential aspect is scalability and future-proofing your project. As technology evolves, your system may need to adapt or expand, requiring motors that can handle increased loads or integrate with new control systems. Look for motors with flexible configurations that allow for adjustments and upgrades, ensuring longevity and efficiency in the project lifecycle.

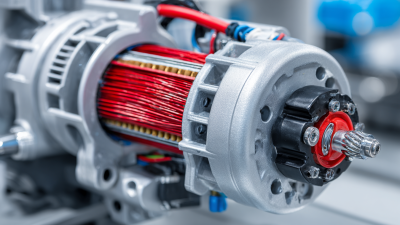

Evaluating Different Types of Motors for Specific Applications

When selecting motors for specific applications, understanding the distinct characteristics of various motor types is crucial. According to a recent report by the International Electromechanical Commission (IEC), DC motors are favored in scenarios requiring precision and speed control, making them ideal for robotics and conveyor systems. With their ability to provide high torque at low speeds, they excel in applications where gradual acceleration is necessary, such as in medical devices or automated processes in manufacturing.

On the other hand, AC motors, particularly asynchronous types, dominate in industrial environments due to their durability and efficiency in high-load operations. A study published by the National Electric Manufacturers Association (NEMA) revealed that over 70% of electric motors used in industrial settings are AC motors. They are often used in fans, pumps, and compressors, where continuous operation and reliability are paramount. For applications requiring variable speed and advanced control, servo motors have gained traction, offering precise position control and repeatability, essential in CNC machinery and automated assembly lines. Each motor type comes with unique advantages that cater to specific application needs, highlighting the importance of careful evaluation during the selection process.

2025 How to Select the Right Motors and Control Systems for Your Project - Evaluating Different Types of Motors for Specific Applications

| Motor Type | Key Features | Advantages | Best Applications | Control System Recommendation |

|---|---|---|---|---|

| DC Motor | Simple structure, easy speed control | High torque at low speeds | Conveyor belts, fans | PWM Controllers |

| Stepper Motor | Precise positioning, digital control | High precision and repeatability | 3D printers, CNC machines | Stepper Driver |

| Servo Motor | Closed-loop control, feedback system | High efficiency and performance | Robotics, automated machinery | Servo Controllers |

| Brushless DC Motor | No brushes, electronic commutation | Long lifespan, low maintenance | Electric vehicles, drones | BLDC Motor Controller |

| AC Induction Motor | Robust, simple design | Cost-effective for larger loads | Pumps, fans, compressors | Variable Frequency Drive (VFD) |

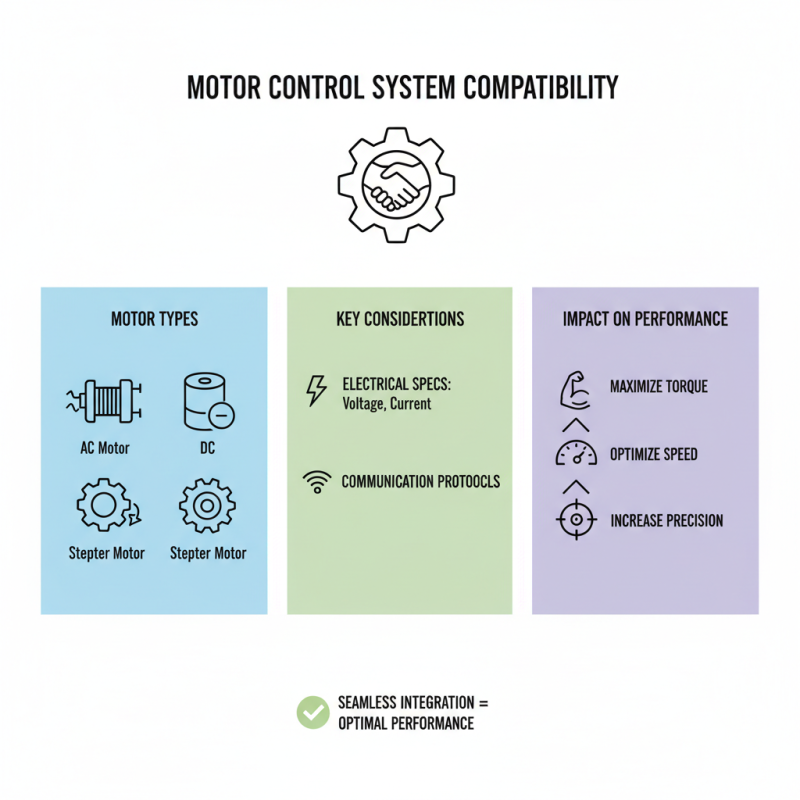

Selecting Control Systems Compatible with Your Motor Choice

When selecting control systems for your motors, compatibility is a paramount consideration that can significantly influence the overall performance and efficiency of your project. Control systems must be designed to work seamlessly with the specific type of motor you are using, whether it is an AC, DC, or stepper motor. This compatibility ensures that the motor can operate within its optimal parameters, maximizing torque, speed, and precision. It is essential to assess not just the electrical specifications, such as voltage and current ratings, but also the communication protocols that will be used for integration.

Additionally, understanding the control requirements of your application can guide your system selection process. For instance, applications that demand precise position control may benefit from advanced servo drive systems, while simpler tasks could rely on basic on/off control systems. It’s critical to evaluate the feedback mechanisms within the control system, such as encoders or sensors, which provide real-time data for better motor management. Ultimately, a well-matched control system enhances responsiveness and reliability, helping to achieve the desired outcomes effectively while minimizing energy consumption and wear on mechanical components.

Integrating Motors and Control Systems for Optimal Performance

Integrating motors with control systems is a crucial aspect of engineering designs aimed at achieving optimal performance in various applications. The selection process begins with a comprehensive understanding of the project requirements, including load characteristics, desired speed, torque, and operational environment. These parameters influence not only the choice of motor type but also the control system's capabilities. For instance, a system intending to perform precise positioning may require a different configuration than one focused on high-speed operations. Careful alignment of these components ensures synergy between motor and controller, enhancing efficiency and reducing energy consumption.

Moreover, the integration of motors and control systems is facilitated by leveraging advanced communication protocols and feedback mechanisms. Implementing closed-loop control enhances responsiveness and accuracy, allowing for real-time adjustments based on operational data. This level of integration enables designers to optimize performance metrics, such as efficiency and reliability, while also addressing potential issues like overheating or excessive wear. Ensuring that motors and control systems work seamlessly together not only improves the immediate performance of the project but also contributes to longevity and maintenance ease, ultimately leading to a successful outcome.

Related Posts

-

2025 Top 10 Innovations in Motors and Control Systems You Must Know

-

Unlocking the Future: How Motors and Control Systems Propel Innovation in Technology

-

Top 5 Benefits of Using Etel Motion for Your Fitness Journey

-

How Semiconductor Companies Are Shaping the Future of Technology Innovation

-

Understanding the Basics of Motor Control: How Your Brain Coordinates Movement

-

Exploring the Future of Semiconductor Career Opportunities in a Rapidly Evolving Industry