Why Motion Control Systems Are Essential for Modern Automation Solutions

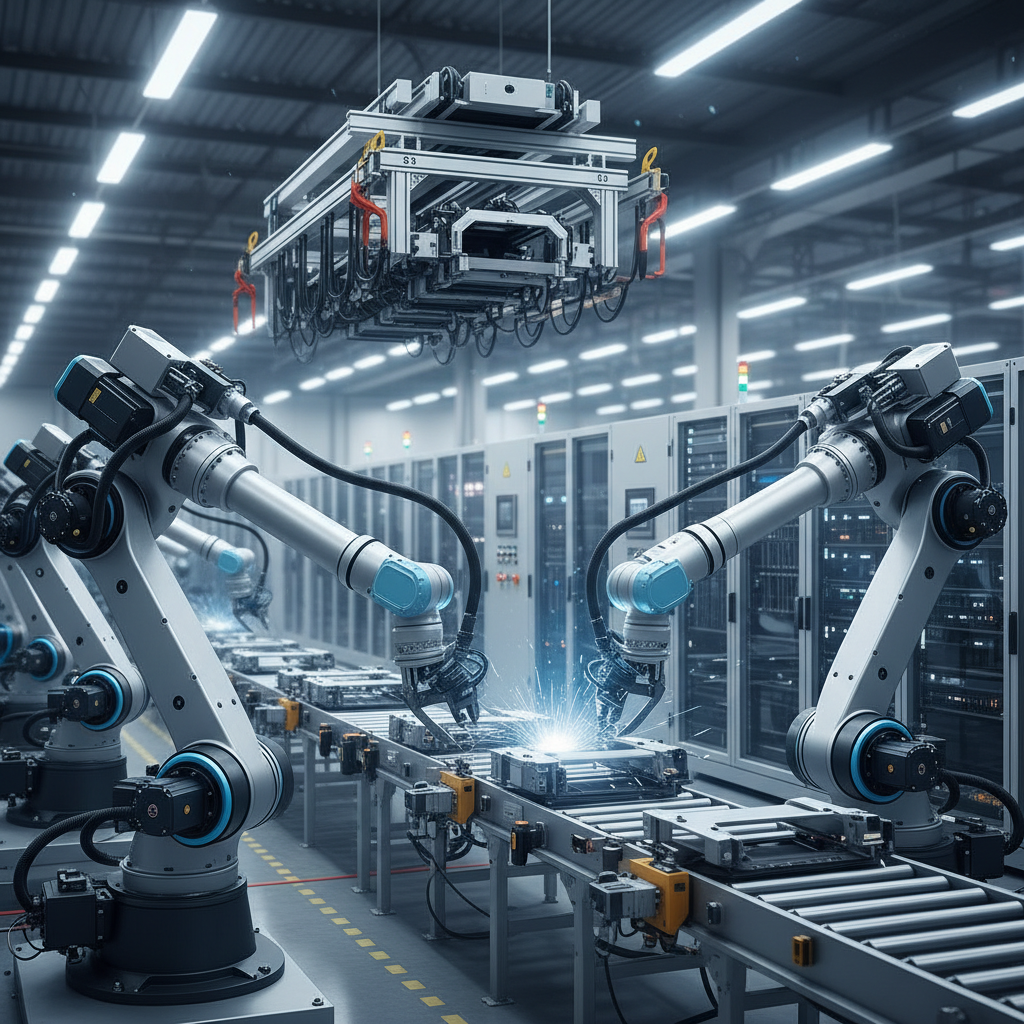

In the rapidly advancing landscape of automation, motion control systems play a pivotal role in enhancing operational efficiency and precision. As industries embrace modern technologies to streamline processes, the demand for sophisticated motion control solutions continues to surge. Renowned expert in the field, Dr. Alice Thompson, has emphasized this importance by stating,

"Motion control systems are the backbone of automation, enabling seamless integration and precise operation of complex machinery."

These systems not only elevate the capabilities of manufacturing equipment but also contribute significantly to reducing downtime and increasing productivity. As we look toward 2025, it is crucial to explore how motion control systems are evolving and why they are indispensable for businesses aiming to thrive in an automated future. By understanding the intricacies of these systems, organizations can leverage their potential to remain competitive and innovative in an ever-changing market landscape.

In this exploration of motion control systems, we will delve into their fundamental components, the latest technological advancements, and the key benefits they offer to modern automation solutions. Through this journey, it will become clear that embracing motion control systems is not just an option but a necessity for organizations striving for excellence in automation.

Importance of Motion Control Systems in Automation

Motion control systems play a pivotal role in modern automation solutions, enhancing efficiency and precision across various industries. According to a report by ResearchAndMarkets, the global motion control market is expected to reach $24.5 billion by 2026, with a compound annual growth rate (CAGR) of 7.7%. This significant growth underscores the increasing reliance on these systems for operational excellence.

The importance of motion control systems in automation lies in their ability to optimize machinery performance and streamline manufacturing processes. These systems enable precise control over speed, position, and torque, which is critical for applications ranging from robotics to conveyor systems. A research study by MarketsandMarkets indicates that effective motion control can reduce production time by up to 20%, thereby significantly improving overall throughput. As industries continue to embrace automation, the integration of advanced motion control technologies becomes essential to maintaining competitiveness and achieving higher productivity levels.

Key Components of Motion Control Systems

Motion control systems are fundamental in today’s automation landscape, integrating several key components that enhance efficiency and precision in various applications. The primary components include controllers, motors, drives, and feedback devices. Controllers analyze the desired movement and send appropriate commands to the motors. Motors, whether they are AC, DC, or stepper, provide the physical motion needed for various tasks. Drives regulate the power supplied to these motors, ensuring they operate smoothly and efficiently. Feedback devices, such as encoders and tachometers, monitor the system's performance, providing real-time data that allows for adjustments to achieve the desired positioning and speed.

Tips: When selecting motion control components, it’s essential to assess compatibility with existing systems and the specific requirements of your application. Pay close attention to the torque and speed ratings of motors, as they directly impact overall performance. Additionally, consider the type of feedback device that will best suit your needs, as this can significantly affect precision and reliability.

The integration of these components into a seamless motion control system enables automation solutions to handle complex tasks with ease. By leveraging technologies like closed-loop control, organizations can improve accuracy and reduce operational costs, thus maximizing productivity. Investing in a robust motion control system is crucial for any business aiming to stay competitive in the rapidly evolving automation sector.

Key Components of Motion Control Systems

Applications of Motion Control in Various Industries

Motion control systems play a pivotal role across various industries, enabling precision and efficiency in automation solutions. In manufacturing, these systems are integral to automated assembly lines, where robots rely on motion control to perform repetitive tasks with high accuracy, significantly reducing production time and costs. Industries such as automotive and electronics benefit from motion control technologies that ensure optimal synchronization and positioning, which are crucial for quality assurance and minimizing waste.

In the field of healthcare, motion control systems are essential for the operation of sophisticated medical devices. Robotic surgical systems utilize advanced motion control to enhance precision during surgeries, allowing for minimally invasive procedures with quicker recovery times. Additionally, in the logistics sector, automated guided vehicles (AGVs) depend on motion control systems to navigate through warehouses efficiently, optimizing the handling and transportation of goods while minimizing human error.

These applications illustrate the versatility and critical importance of motion control systems across diverse industries, driving innovation and productivity in modern automation solutions.

Benefits of Integrating Motion Control in Modern Solutions

The integration of motion control systems in modern automation solutions brings forth a myriad of benefits that enhance operational efficiency and precision. One significant advantage is the improvement of production speed and accuracy. By utilizing advanced motion control technologies, businesses can achieve faster cycle times and reduce errors during manufacturing processes. This results in higher productivity levels and ultimately leads to increased profitability.

Furthermore, motion control systems offer unparalleled flexibility in automation. They can easily adapt to various tasks and changing production requirements, allowing companies to stay competitive in a rapidly evolving market. With the ability to program and reconfigure systems swiftly, businesses can respond to new product demands without significant downtime. This adaptability not only streamlines operations but also minimizes operational costs.

In addition, the integration of motion control enhances system monitoring and diagnostics, enabling proactive maintenance and reducing the risk of unexpected equipment failures. By providing real-time feedback and performance data, these systems empower operators to make informed decisions, ensuring optimal operation and longevity of machinery. Overall, the incorporation of motion control into modern automation solutions significantly elevates the capabilities and reliability of automated processes.

Future Trends in Motion Control for Automation Technologies

The future of motion control in automation technologies is shaped by rapid advancements in artificial intelligence, machine learning, and Internet of Things (IoT) integration. According to a recent report by MarketsandMarkets, the motion control market is projected to grow from $19.6 billion in 2023 to $28.6 billion by 2028, reflecting a compound annual growth rate (CAGR) of 7.6%. This growth is driven by the increasing need for precision and efficiency in manufacturing processes, as more industries adopt automated solutions to enhance productivity and reduce costs.

In addition, the development of smart motion control systems is poised to revolutionize how machinery operates. These systems leverage real-time data analytics and predictive maintenance, enabling manufacturers to minimize downtime and optimize performance. A study by Transparency Market Research indicates that the global market for smart manufacturing technologies, which includes advanced motion control systems, will reach $530 billion by 2025. As these technologies evolve, they promise to deliver not just improved operational efficiency but also greater flexibility in production, accommodating customization and rapid changes in consumer demand. The future of automation will undeniably rely on innovative motion control solutions that can adapt to an ever-changing industrial landscape.

Related Posts

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

10 Best Etel Motion Products for Ultimate Comfort and Style in 2023

-

10 Best Etel Motors Models You Need to Know for 2024

-

Unlocking the Future of Therapy: How Etel Motion Transforms Movement Rehabilitation

-

Exploring the Future of Motor Control Solutions: Innovations That Drive Efficiency and Precision