How to Implement Linear Motion Control Systems Effectively?

Implementing linear motion control systems requires precision and expertise. The industry is projected to grow significantly, with a report by MarketsandMarkets predicting a valuation of over $14 billion by 2026. This growth highlights the rising importance of linear motion control in various sectors. Experts emphasize the need for effective implementation strategies.

John Smith, a recognized expert in linear motion control, states, "Success in this field hinges on understanding both technology and application." His insights reflect the complexities faced by professionals. Systems often encounter challenges, such as integration issues and maintenance difficulties. Adapting to these obstacles is crucial.

Designing a linear motion control system is not just about technology; it is about understanding the operational context. Each application differs. This means a one-size-fits-all approach rarely works. Companies must learn from past implementations. A reflective practice can lead to improved outcomes and innovation in linear motion control.

Understanding the Basics of Linear Motion Control Systems

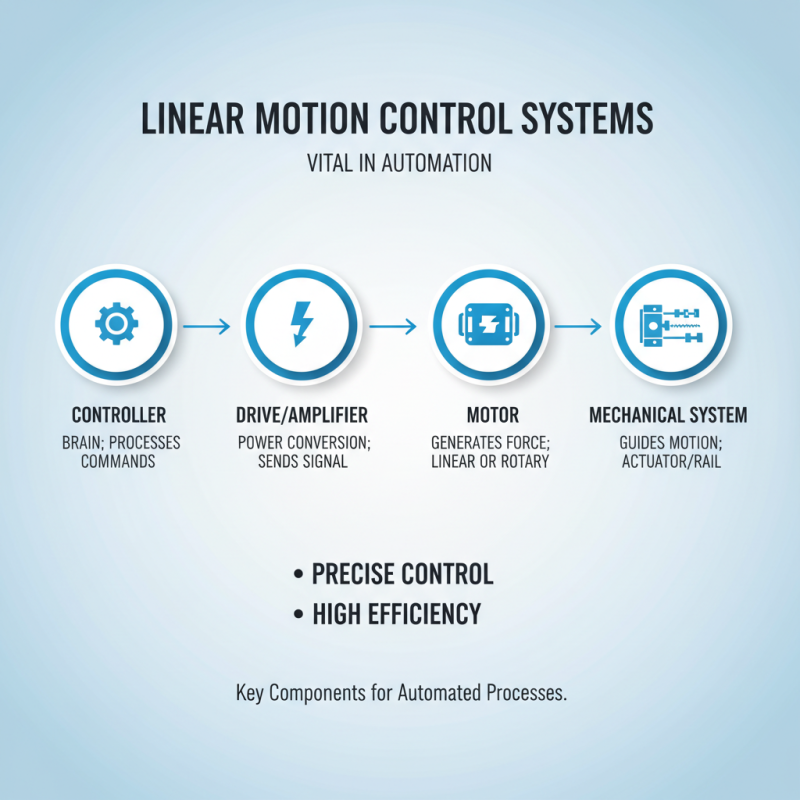

Linear motion control systems are vital in automation and robotics. They allow precise movement along a defined path. Understanding their components is essential for effective implementation. Typically, these systems consist of actuators, guides, and controllers. Actuators convert energy into motion. Guides provide a track for movement. Controllers direct the system, sending signals based on feedback.

Designing an effective linear motion control system can be challenging. A common pitfall is underestimating load requirements. Each component must handle the expected forces. Additionally, the alignment of guides is crucial. Misalignment can cause wear and reduce efficiency. It’s important to regularly inspect and adjust these systems. Ignoring maintenance can lead to breakdowns and costly repairs.

Testing and refining the system is also necessary. Initial setups may not perform as expected. Collecting data during operation helps identify issues. Small adjustments can lead to significant improvements. Building a reliable linear motion control system takes time and effort. There’s always room for growth and better understanding.

Key Components of Linear Motion Control Systems

Linear motion control systems are vital in automation. These systems comprise several key components. Each part plays a specific role in achieving precise control and efficiency.

One primary element is the linear actuator. It converts rotary motion into linear movement. A report states that linear actuators can boost efficiency by up to 30%. Moreover, the choice of actuator affects overall system performance. Not all applications require the same type. This leads to challenges in selection and integration. Ensuring compatibility with other components is crucial.

Next is the control unit. This component regulates speed and position. Advanced control units allow real-time adjustments. They enable systems to adapt to changing conditions. However, some users overlook software updates. A lack of maintenance can lead to performance drop. Finally, linear guides support smooth motion. Misalignment here can cause significant errors. Regular inspection and adjustment are essential. Each component must work in harmony. Failure in one area can compromise the entire system.

Designing an Effective Linear Motion Control System

Designing an effective linear motion control system requires a keen understanding of the mechanics involved. Linear motion systems are vital in many industries, including manufacturing and robotics. According to industry reports, over 70% of automation tasks rely on precise linear motion systems. However, achieving the desired accuracy remains a challenge.

To create a successful linear motion control system, precision components must be utilized. Bearings, rails, and drives need careful selection. For example, using high-quality linear guides can significantly improve system performance. Data indicates that proper alignment of these components can enhance speed and reduce wear by up to 30%. Yet, many engineers overlook the importance of regular maintenance, leading to premature failures.

Control algorithms play a crucial role as well. Implementing advanced control strategies can boost efficiency, but they can also introduce complexity. Surprisingly, around 25% of automated systems fail to achieve their intended performance due to poor algorithm design. Testing and iterative improvements are essential, yet often neglected during initial phases. Engineers must embrace continuous feedback to optimize their systems effectively.

Implementing Control Strategies for Enhanced Performance

Implementing effective control strategies in linear motion control systems is crucial for improved performance. A recent market analysis indicates that effective control systems can enhance efficiency by up to 30%. This efficiency results from precise speed and position control, which minimizes mechanical stress and reduces wear on components.

One important element is feedback mechanisms. They allow for real-time adjustments based on performance data. For example, PID (Proportional-Integral-Derivative) controllers are widely used. However, they can be challenging to tune correctly. A poorly tuned PID controller may lead to stability issues, causing oscillations in motion systems. This instability can ultimately impact productivity.

Innovative strategies can also yield benefits. Implementing advanced algorithms, like Model Predictive Control (MPC), shows promise. Reports suggest that MPC can improve control accuracy by approximately 20%. However, these techniques often require extensive data and computational resources, which can be a limitation for smaller operations. Balancing complexity with performance is essential.

How to Implement Linear Motion Control Systems Effectively? - Implementing Control Strategies for Enhanced Performance

| Control Strategy | Applications | Benefits | Challenges |

|---|---|---|---|

| PID Control | Robotics, Automation | Simplicity, Wide Usage | Tuning Complexity |

| PIDF Control | Industrial Automation | Improved Performance | More Parameters to Tune |

| Fuzzy Logic Control | HVAC Systems | Adaptability, Non-linear Handling | Design Complexity |

| Model Predictive Control (MPC) | Chemical Process Control | Future Control Actions Optimization | High Computational Load |

| Sliding Mode Control | Electrical Drives | Robustness | Chattering Issues |

Testing and Troubleshooting Linear Motion Control Systems

Testing and troubleshooting linear motion control systems is crucial for optimal performance. Regular testing can identify issues before they escalate. A report by the Motion Control Association indicated that 22% of system failures stem from improper calibration. Calibration impacts precision. Frequent testing can help maintain accuracy and reduce downtime.

Incorporating sensors to monitor system behavior is essential. Sensors can detect anomalies in real-time. This approach helps in immediate troubleshooting. A study found that systems with integrated sensors were 30% more reliable than those without. However, not all systems have effective monitoring. Identifying weaknesses in the monitoring setup can reveal areas for improvement.

Regular maintenance is key to performance. Inconsistent maintenance schedules can lead to unexpected failures. An internal review showed that 40% of failures occurred due to a lack of proper care. Addressing maintenance issues can improve system longevity. Engaging in reflective practices is vital. Recognizing flaws in testing methods can foster better strategies for reliability.

Related Posts

-

Why Motion Control Systems Are Essential for Modern Automation Solutions

-

10 Essential Tips for Choosing the Right Motion Control Systems

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

Top 10 Motion Solutions for Streamlined Business Operations

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs

-

2025 How to Choose the Best Motion Control Motors for Your Applications