10 Essential Tips for Understanding Motors and Control Systems Effectively

In the rapidly evolving field of motors and control systems, understanding the intricacies of these technologies is crucial for both professionals and enthusiasts alike. As industry expert Dr. Jane Smith, a leading researcher in motor technologies, once stated, "A deep understanding of motors and control allows us to unlock unprecedented efficiencies and innovations in automation." This sentiment underscores the importance of mastering the core principles that govern how these systems operate.

Motors and control systems are foundational elements in a wide variety of applications, from manufacturing processes to robotics. However, many individuals may find themselves overwhelmed by the technical complexities involved. To navigate this landscape effectively, it is essential to grasp key concepts such as motor types, control strategies, and system integration. With the right insights and guidelines, anyone can enhance their knowledge and proficiency in these vital areas. The following tips are designed to demystify the world of motors and control, providing practical advice to help you achieve mastery and foster innovation in your projects.

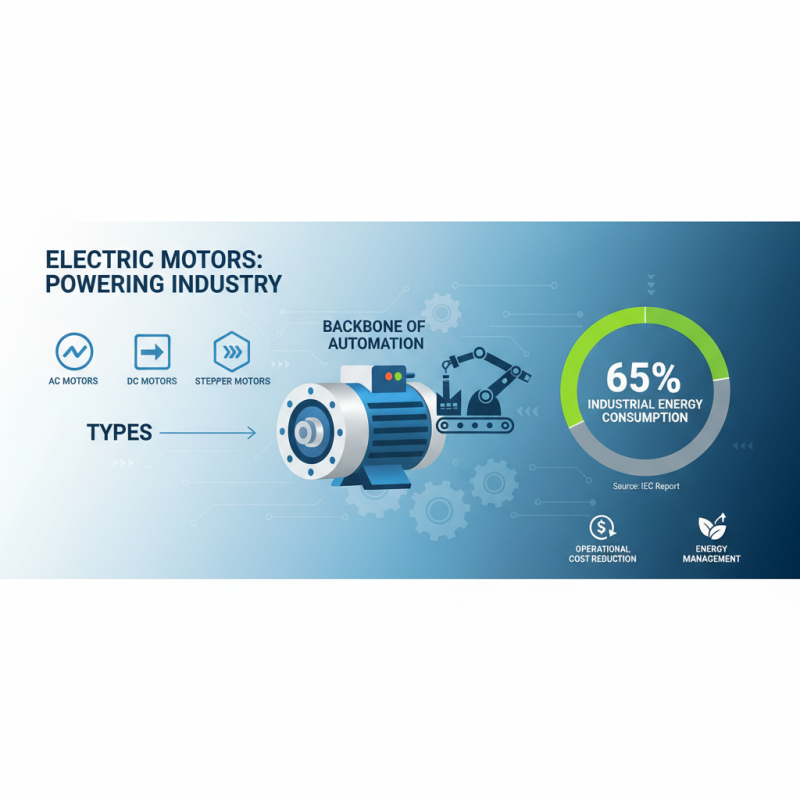

Fundamentals of Electric Motors: Types and Applications

Electric motors are integral to numerous applications across various industries, operating as the backbone of automation and control systems. The types of electric motors primarily include AC motors, DC motors, and stepper motors, each serving distinct purposes. AC motors, commonly used in industrial settings, are known for their reliability and efficiency when converting electrical energy into mechanical motion. According to a report by the International Electrotechnical Commission (IEC), approximately 65% of the total energy consumed by industrial facilities is attributed to electric motors, underscoring their significance in energy management and operational cost reduction.

DC motors, on the other hand, excel in applications requiring precise control over speed and torque, making them ideal for robotics and automotive industries. The rise of electric vehicles has further propelled the demand for high-performance DC motors, with market projections estimating a compound annual growth rate (CAGR) of 22.2% from 2022 to 2028 for the electric motor market, as reported by Allied Market Research. Stepper motors are increasingly favored in manufacturing and 3D printing due to their ability to provide accurate positioning and repeatability, crucial for modern automation processes.

Understanding the applications and specifications of these motor types is vital for selecting the right motor for a given task. Factors such as torque requirements, operational environment, and control mechanisms play a crucial role in determining the most suitable motor. As industries continue to innovate, staying updated with the latest advancements in electric motor technologies will be essential for engineers and technicians to optimize performance and enhance efficiency.

Key Components of Control Systems: An Overview

Control systems serve as the backbone of motor function and automation, comprising several key components that work in tandem to ensure efficient operation. At the heart of any control system is the controller, which processes input signals and determines the necessary output actions to maintain desired performance levels. This component often includes algorithms that regulate system behavior, making it crucial in achieving precise control over motor applications.

Another integral aspect of control systems is the sensor, which monitors the output of the system and relays real-time data back to the controller. Sensors can measure various parameters such as speed, temperature, and position, enabling the controller to adjust its actions accordingly. Additionally, actuators play a significant role by receiving control signals and executing the necessary movements to achieve the desired outcomes. Together, these components create a feedback loop that enhances the effectiveness and reliability of motors and control systems, allowing for improved performance in numerous applications.

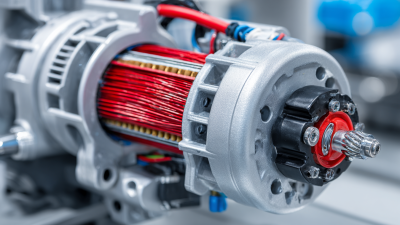

Understanding Motor Specifications and Ratings

Understanding motor specifications and ratings is crucial for effectively utilizing motors in various applications. Motors are typically rated based on key specifications such as power output, efficiency, torque, and speed. According to a report by the International Electrotechnical Commission, understanding these parameters can enhance the selection process, ensuring that the right motor is chosen for the specific application, ultimately leading to improved performance and energy efficiency. For instance, a motor’s efficiency rating, often expressed as a percentage, indicates how effectively it converts electrical energy into mechanical energy. Motors with higher efficiency ratings tend to incur lower operating costs over time.

Another significant aspect of motor specifications is the torque rating, which measures the rotational force the motor can provide. A study published in the IEEE Transactions on Industrial Electronics highlights that torque is critical in applications requiring precise motion control, such as robotics and conveyor systems. Selecting a motor with adequate torque capabilities ensures that tasks are performed smoothly without stalling or excessive wear on the system. Additionally, understanding the relationship between speed and torque in different types of motors, such as AC and DC motors, can further optimize the performance in varied operational conditions. By comprehensively analyzing motor specifications and ratings, engineers and technicians can make informed decisions that enhance performance, reliability, and overall system efficiency.

Principles of Feedback and Control in Motor Systems

The principles of feedback and control in motor systems are vital for enhancing performance, reliability, and efficiency. Feedback control systems continuously monitor the output of a motor to adjust its operation in real time, ensuring that desired performance levels are achieved. According to a report by the International Society of Automation, nearly 75% of industrial facilities have implemented some form of feedback control, underscoring its significance in modern automation practices. This system allows for corrections based on real-time data, leading to reduced energy consumption and improved operational precision.

The effectiveness of these feedback mechanisms heavily relies on the proper tuning of control parameters, such as gain and response time. Research indicates that optimized control settings can yield a 30-50% increase in motor efficiency, translating to significant cost savings in energy usage. Furthermore, the integration of advanced control algorithms, such as PID (Proportional-Integral-Derivative) controllers, has become fundamental for achieving better dynamic responses and stability in motor operations. As industries continue to pursue automation and demand higher efficiency, the role of advanced feedback mechanisms remains crucial in driving innovations in motor control systems.

Understanding Motors and Control Systems

This chart illustrates the efficiency and performance metrics of different motor types commonly used in control systems, highlighting the principles of feedback and control.

Troubleshooting Common Issues in Motors and Control Systems

Motor and control systems are integral components in various applications, but they can often face operational issues that require effective troubleshooting techniques. One common problem is overheating, which can arise from excessive load or insufficient ventilation. To address this, it's essential to monitor operational conditions and ensure that motors are adequately cooled and not subjected to loads beyond their rating. Regular maintenance checks can help identify potential overheating issues before they lead to system failure.

Another frequent challenge is inconsistent performance, which could manifest as erratic speed or unresponsive control. This may be caused by faulty sensors, loose connections, or inadequate power supply. It’s crucial to systematically check these elements, ensuring that all electrical connections are secure and that sensors are functioning correctly. Additionally, inspecting the power supply for fluctuations can help identify if external factors are influencing motor performance. By methodically addressing these common issues, one can enhance the reliability and efficiency of motor and control systems.

Related Posts

-

2025 How to Select the Right Motors and Control Systems for Your Project

-

Unlocking the Future: How Motors and Control Systems Propel Innovation in Technology

-

Understanding the Basics of Motor Control: How Your Brain Coordinates Movement

-

Unlocking the Mysteries of Motor Control: How Your Brain Powers Movement

-

2025 Top 10 Innovations in Motors and Control Systems You Must Know

-

2025 How to Choose the Best Motion Control Motors for Your Applications