10 Essential Tips for Choosing Motor Control Solutions for Your Business?

Selecting the right motor control solutions for your business can be a daunting task. Industry expert James Thompson, a leading figure in automation technology, once said, "The right motor control solution can propel your business forward." Understanding your specific needs is essential.

Motor control solutions vary significantly in functionality and capability. It’s crucial to consider the unique requirements of your applications. Not all solutions fit every scenario. Sometimes, the best option may not be the most advanced or expensive, but the one that meets your precise demands.

Moreover, the implementation of motor control solutions may present challenges. Companies often overlook integration with existing systems. This could lead to inefficiencies or increased costs. Reflecting on these details is vital to making an informed choice. Balancing features, costs, and compatibility will ensure the best outcome for your operations.

Key Considerations for Assessing Motor Control Solutions Performance Metrics

When selecting motor control solutions, performance metrics are crucial. Evaluating metrics ensures that the chosen solution meets industry standards. For instance, a recent report from the International Electrotechnical Commission indicated that efficient motor control can improve energy savings by up to 30%. This is significant for any business looking to reduce operational costs.

Tip 1: Look for efficiency ratings. These ratings reveal how much energy will be consumed during operation. It's essential to analyze energy consumption in real-time, allowing for adjustments based on actual needs. If solutions do not provide clear data, reconsider your options.

Additionally, consider the adaptability of the motor control solutions. According to a recent survey by the Motor & Motion Control Association, 50% of businesses prefer solutions that integrate easily with existing systems. If a product cannot sync with your current setup, it may lead to unnecessary downtime and increased costs.

Tip 2: Assess the user interface. A complex interface can hinder quick adjustments. Simplified controls promote better decision-making. If users struggle with settings, performance may decline. Focus on solutions that strike a balance between advanced functionalities and user-friendliness.

Understanding these metrics will guide businesses toward efficient motor control solutions capable of enhancing productivity and reducing costs.

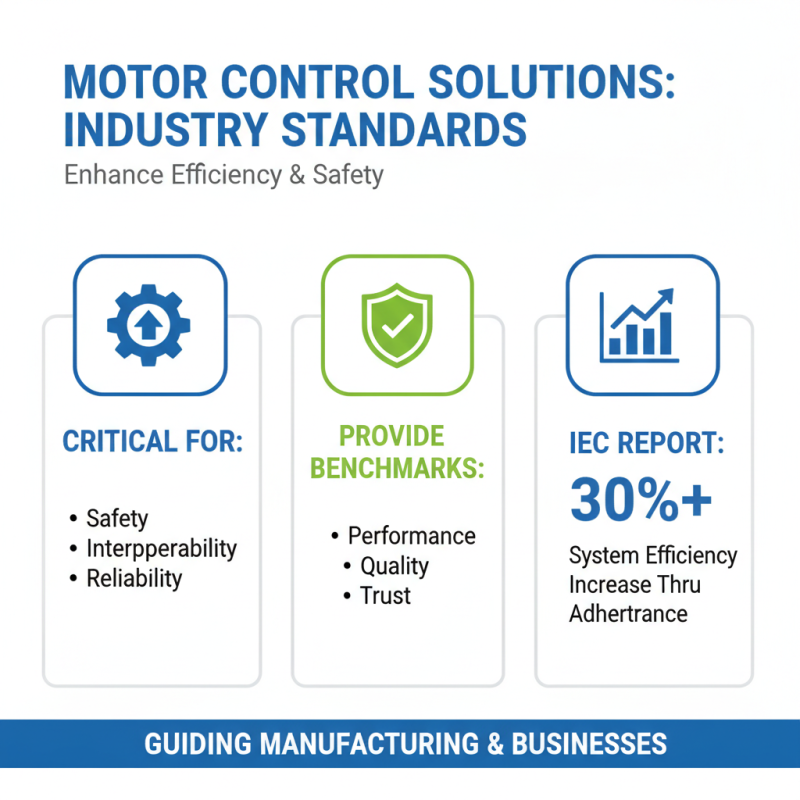

Understanding the Importance of Industry Standards in Motor Control Selection

When selecting motor control solutions, understanding industry standards is critical. Standards ensure safety, interoperability, and reliability in operations. They provide benchmarks for performance, essentially guiding manufacturers and businesses. A report by the International Electrotechnical Commission highlights that adherence to predefined standards can enhance system efficiency by over 30%.

However, standards can sometimes limit innovation. Some cutting-edge technologies may not fit neatly into existing framework guidelines. Therefore, it is essential to balance compliance and creativity. The lack of flexibility might hinder the adoption of advanced motor control solutions that could drive efficiency.

Moreover, many businesses underestimate the importance of staying updated on evolving standards. The National Electrical Manufacturers Association notes that 45% of manufacturing plants faced compliance issues due to outdated equipment. Regularly reviewing standards can save businesses from costly downtime and potential safety hazards. By proactively aligning with industry standards, companies can better position themselves for growth and innovation.

Evaluating Cost-Effectiveness: Total Cost of Ownership in Motor Solutions

When evaluating motor control solutions, understanding the total cost of ownership (TCO) is crucial. TCO includes purchase price, installation, maintenance, and operational costs. Future expenses can creep up if not accounted for initially. Hidden costs, like energy consumption and downtime, can increase overall expenses.

Consider the efficiency ratings of the solutions you’re exploring. A more efficient motor may have a higher upfront cost but lower energy bills. This can significantly reduce TCO over time. Make sure the solution aligns with your operational needs. Quick take: assess your workload and how often motors run.

Another essential tip is to look at warranty and support. A longer warranty can indicate manufacturer confidence. However, reflect on what happens after the warranty period. Will the support be sufficient? Consider training requirements for staff. Ensure they can operate and maintain the solution efficiently. This can prevent future frustrations and costs.

Analyzing Reliability and Maintenance Needs of Motor Control Systems

When selecting motor control systems, understanding reliability and maintenance needs is crucial. According to a recent industry report, nearly 30% of motor failures are due to inadequate maintenance practices. This highlights the need for businesses to evaluate the long-term performance of their motor control solutions. Regular maintenance can prevent abrupt failures and reduce downtime. In fact, companies that invest in proactive maintenance can see operational costs drop by up to 25%.

Another key aspect to consider is the environment in which the systems operate. Harsh conditions—like high temperatures or moisture—can drastically affect reliability. A well-designed motor control system should withstand these challenges. However, not all systems perform equally under stress. Businesses should review system specifications and conduct thorough risk assessments. Data indicates that inadequate environmental adaptation can lead to performance drops of 40%, emphasizing the need for careful consideration.

Lastly, training staff on maintenance protocols is often overlooked. Many companies assume their systems are reliable without understanding the importance of human factors. Poorly trained personnel can lead to improper maintenance and increased repair costs. Employees need to grasp not only how to operate the system but also how to recognize early warning signs of failure. Investing in employee training can enhance the reliability of motor control systems significantly.

Analyzing Reliability and Maintenance Needs of Motor Control Systems

Comparing Energy Efficiency Ratings for Sustainable Motor Control Solutions

Energy efficiency in motor control solutions is crucial for sustainable business practices. When comparing options, look for solutions that reduce energy consumption. Check the energy efficiency ratings provided by manufacturers. These ratings often show how much power a motor uses compared to its output. A higher rating typically means better efficiency. This can significantly lower operating costs over time.

However, energy ratings may not tell the whole story. It is essential to consider the specific needs of your business. Some solutions may be rated highly but lack the adaptability for certain applications. Take into account how these solutions perform under varying loads. A system that is efficient at a peak load may not be effective at lower capacities. Balancing these aspects can lead to a more tailored solution.

Furthermore, installation and maintenance can impact overall efficiency. An efficient motor control solution may require advanced installation techniques. This can cause initial hesitation in selection. Training staff for proper use is also a concern. When choosing, consider long-term impacts. Sustainable practices often require short-term sacrifices. A well-rounded evaluation can guide you in making a more informed decision.

Related Posts

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs

-

Why Motion Control Systems Are Essential for Modern Automation Solutions

-

How to Implement Linear Motion Control Systems Effectively?

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

Exploring the Future of Motor Control Solutions: Innovations That Drive Efficiency and Precision

-

10 Best Etel Motion Products for Ultimate Comfort and Style in 2023