Understanding Direct Drive Linear Motors and Their Applications in Industry

In recent years, the manufacturing sector has witnessed a significant transformation thanks to advancements in technology, with the direct drive linear motor emerging as a pivotal innovation. These revolutionary motors offer unparalleled precision and efficiency in various industrial applications, streamlining processes in sectors ranging from automotive to packaging. According to Dr. Emily Huang, a leading expert in automation technologies, “Direct drive linear motors provide not only the highest level of accuracy but also reduce maintenance costs, making them ideal for modern manufacturing needs.”

As industries strive for greater productivity and reduced operational costs, the direct drive linear motor stands out for its ability to eliminate mechanical components traditionally associated with linear motion systems. By providing a direct connection between motor and load, these motors mitigate the need for belts, gears, and other elements, ultimately enhancing reliability and performance. Dr. Huang further emphasizes, “The integration of direct drive linear motors in production lines signifies a move towards more streamlined and efficient manufacturing processes.”

This paradigm shift in motion control highlights the importance of understanding direct drive linear motors and their wide-ranging applications. With their growing presence in automated systems, it becomes essential for industries to grasp the benefits and potentials of this innovative technology to remain competitive in today's fast-paced market.

Understanding the Principles of Direct Drive Linear Motors

Direct drive linear motors (DDLMs) represent a significant advancement in motion control technology, employing a unique design that eliminates the need for gear systems and provides direct translation of electrical energy into linear motion. By using electromagnetics, these motors generate linear force directly on the load, resulting in increased efficiency and precision. According to a report by MarketsandMarkets, the global linear motor market was valued at approximately $1.5 billion in 2022 and is projected to reach around $2.2 billion by 2027, highlighting the growing adoption of this technology across various industries.

The principles of direct drive linear motors hinge on the interaction between magnetics and electric current. When an electric current flows through the coils wound on the stator, it creates a magnetic field that interacts with magnets placed on the moving component, producing linear motion. This setup not only reduces mechanical wear and tear due to fewer moving parts but also enhances performance in terms of speed and accuracy. The precision positioning capabilities of DDLMs are essential in sectors like semiconductor manufacturing and precision machining, where small deviations can lead to significant quality control issues and increased costs. A detailed analysis by Research and Markets indicates that the demand for precise and high-speed motion control in automation systems is a primary driver for the adoption of linear motors, with an estimated growth rate of over 10% annually in these sectors.

Benefits of Using Direct Drive Linear Motors in Industrial Applications

Direct drive linear motors are revolutionizing industrial applications by providing unparalleled precision, speed, and efficiency. Unlike traditional motors that rely on mechanical components to transfer motion, direct drive linear motors create motion through electromagnetic forces, resulting in a more reliable and maintenance-free operation. This technology minimizes backlash and enables rapid acceleration and deceleration, making it ideal for tasks requiring high accuracy and responsiveness.

One of the most significant benefits of using direct drive linear motors in industrial settings is their ability to enhance productivity. With fewer moving parts, these motors reduce wear and tear, leading to longer operational lifespans and less downtime for maintenance. Furthermore, their compact design allows for integration into tight spaces where conventional motors might be impractical, streamlining production processes and optimizing overall system performance.

Tips for implementing direct drive linear motors include assessing the specific application requirements and ensuring a suitable power supply for optimal performance. It's essential to consider the environment; if it involves dust or extreme temperatures, motors with protective features are recommended. Additionally, when integrating these motors into existing systems, thorough testing is crucial to ensure seamless operation and maximize the benefits of this advanced technology.

Understanding Direct Drive Linear Motors and Their Applications in Industry

| Application Area | Benefits | Key Features | Typical Load Capacity | Speed Range |

|---|---|---|---|---|

| Material Handling | High precision and reduced maintenance | Non-contact motion | Up to 500 kg | 1 m/s - 3 m/s |

| Packaging Machinery | Increased throughput and efficiency | Fast response time | Up to 300 kg | 2 m/s - 5 m/s |

| Automotive Assembly | Enhanced flexibility and scalability | Modular design | Up to 1000 kg | 0.5 m/s - 4 m/s |

| Textile Industry | Reduced vibration and noise | High acceleration | Up to 200 kg | 1 m/s - 2 m/s |

| Electronics Manufacturing | Improved accuracy and repeatability | Precision control | Up to 150 kg | 0.5 m/s - 3 m/s |

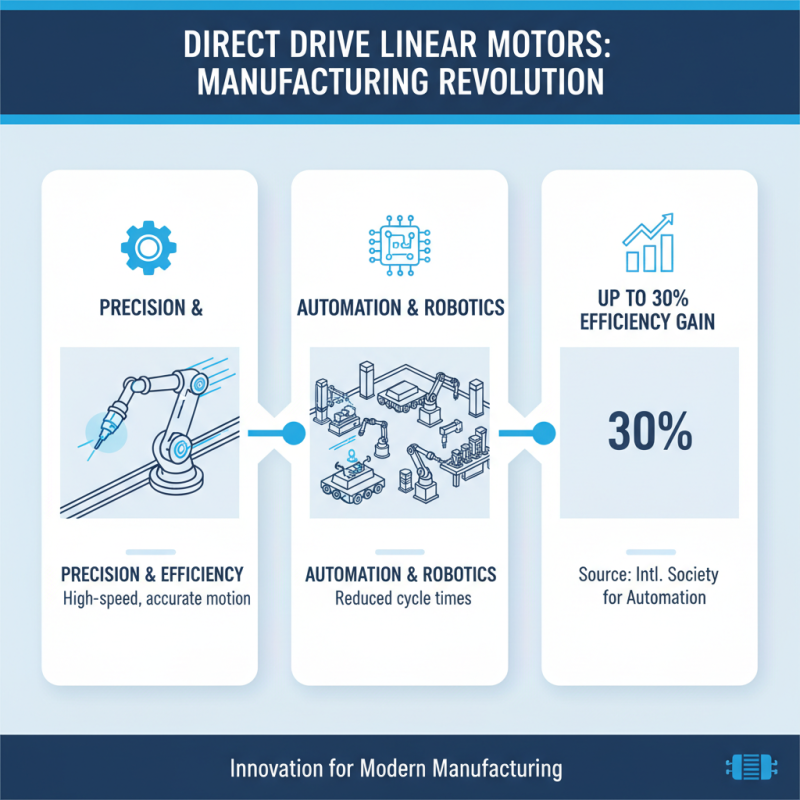

Common Applications of Direct Drive Linear Motors in Manufacturing

Direct drive linear motors (DDLMs) are revolutionizing the manufacturing landscape, offering precision and efficiency across various applications. One of the most common implementations of DDLMs is in automation and robotic systems where their ability to deliver high-speed and accurate motion significantly reduces cycle times. According to a recent report by the International Society for Automation, industries utilizing direct drive systems have witnessed efficiency increases of up to 30%, further underscoring their growing importance in modern manufacturing.

In material handling, DDLMs facilitate rapid and reliable movement of goods, enhancing warehouse operations and production lines. For instance, their use in conveyor systems helps minimize friction loss and energy consumption, leading to an estimated 20% reduction in operational costs as highlighted in the Automation World 2022 Industry Report. The precision and responsiveness of these motors also play a critical role in applications such as CNC machining, where maintaining strict tolerances is essential for product quality.

Tips: When considering the integration of direct drive linear motors, it’s crucial to assess the specific requirements of your application, such as load type and motion profile. Additionally, ensure proper sizing and configuration to take full advantage of their capabilities, which can yield significant returns in efficiency and output quality. Always keep an eye on advancements in motor technologies, as continuous innovations could open new avenues for improved performance and cost savings in your operations.

Challenges and Limitations of Direct Drive Linear Motors

Direct drive linear motors offer significant advantages, such as high precision and efficiency, in various industrial applications. However, they also present several challenges and limitations that must be addressed to maximize their potential. One of the primary challenges is the requirement for advanced control systems. Unlike traditional systems, direct drive linear motors demand sophisticated algorithms to manage their high-speed and high-acceleration capabilities, making them more complex to implement and maintain.

Another critical limitation is the thermal management issue associated with direct drive linear motors. As these motors operate at high performance levels, they generate substantial heat, which can affect their efficiency and longevity. Proper cooling solutions must be integrated into the design to ensure optimal performance, adding to the overall system complexity and cost. Additionally, the magnetic levitation and alignment required for these motors necessitate precise installation and calibration, which can pose challenges in varying operational environments. These factors highlight the need for careful consideration when integrating direct drive linear motors into industrial applications.

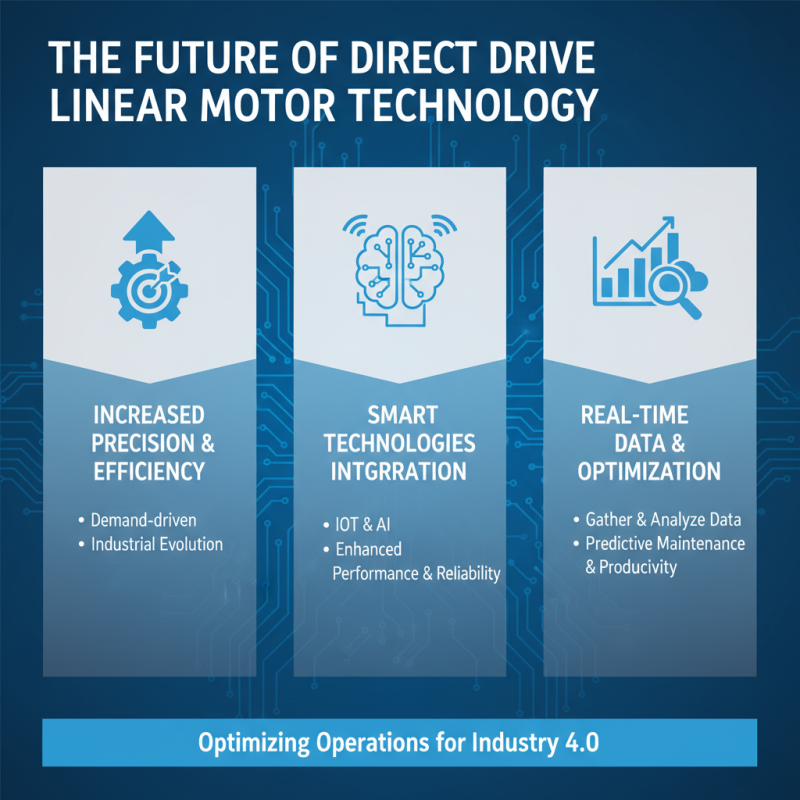

Future Trends in Direct Drive Linear Motor Technology

The future of direct drive linear motor technology is poised for significant advancements, driven by the demand for increased precision and efficiency in industrial applications. As industries continue to evolve, the integration of smart technologies, such as IoT and AI, into linear motor systems will enhance their performance and reliability. The ability to gather and analyze data in real-time allows manufacturers to optimize operations, anticipate maintenance needs, and ultimately improve productivity.

Tips: When considering the adoption of direct drive linear motors, assess your specific application requirements carefully. Evaluate factors such as load capacity, required speed, and space constraints to ensure the selected motor aligns with your operational goals.

Additionally, the trend towards sustainability cannot be overlooked. Future direct drive linear motors will likely focus on energy efficiency and reduced environmental impact. With innovations in materials, such as lighter composites and better thermal management, these motors could operate more effectively while consuming less energy. This will not only help companies lower their operating costs but also contribute positively to their sustainability initiatives.

Tips: Keep abreast of technological advancements and engage with suppliers who invest in research and development for cutting-edge solutions. This proactive approach will help you stay ahead in adopting the most efficient tools for your production needs.

Related Posts

-

The Future of Automation with Etel Linear Motors What You Need to Know

-

Top PCB Companies of 2025: What to Look for in Quality and Innovation?

-

2025 Guide: How to Improve Motor Control for Better Performance

-

2025 Top 5 Electronics Tools to Enhance Your Productivity and Creativity

-

10 Best Etel Motion Products for Ultimate Comfort and Style in 2023

-

Top 5 Benefits of Using Etel Motion for Your Fitness Journey