2026 How to Choose the Right PCB Company for Your Needs?

Finding the right PCB company can be challenging. The electronics industry is vast, with many options. Having guidance can make a difference. John Smith, a leading expert in PCB services, once stated, "Choosing a PCB company is about aligning their strengths with your project needs."

Consider the specific requirements of your project. Does the company specialize in the type of PCB you need? Look for a PCB company that understands your industry and offers tailored solutions. Quality and cost are also crucial factors. Sometimes, a low price may compromise quality. Be cautious and do your homework.

Visualize your project goals. A trustworthy PCB company should be able to provide clear timelines and transparent communication. Scrutinize their past work. Mistakes often stem from miscommunication or lack of expertise. Reflect on what makes a successful partnership. It’s more than just signing a contract; it’s about building a relationship that fosters trust and innovation.

Understanding Your PCB Requirements and Specifications

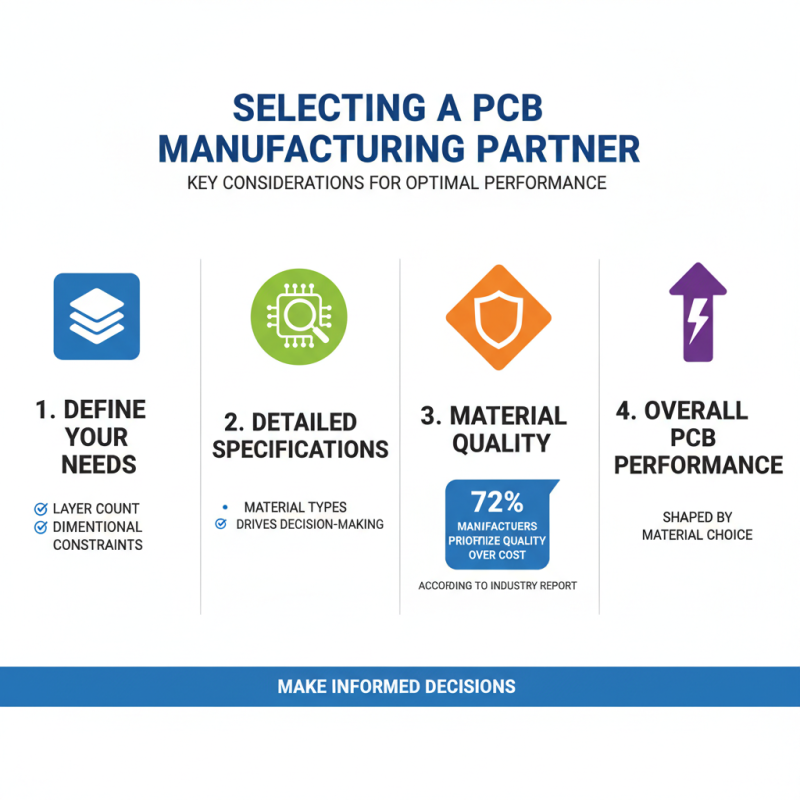

When selecting a PCB company, understanding your requirements is crucial. Detailed specifications drive the decision-making process. Consider factors like layer count, material types, and dimensional constraints. According to a recent industry report, 72% of manufacturers prioritize material quality over cost. This realization shapes the overall performance of the PCB.

Design complexity often influences manufacturing capabilities. An IPC-6012 standard indicates that intricate designs require specific expertise. Companies frequently report struggles with meeting tight deadlines while ensuring high-quality standards. About 46% of firms encountered challenges in production due to unclear specifications. Clarity saves time and reduces errors.

It's essential to reflect on your changing needs. Flexibility may become necessary as projects evolve. Remember, the right company will adapt to your growing requirements while maintaining quality. Research into potential partners is key. Yet, not all companies excel at communication. This gap can lead to misunderstandings. Effective collaboration can turn project dreams into realities.

Evaluating the Capabilities and Expertise of PCB Companies

When choosing a PCB company, evaluating their capabilities is essential. Start by looking at their manufacturing technology. Advanced equipment often leads to better quality. Check if they can handle complex designs and different materials. Some companies shine with high-volume orders, while others may struggle.

Tips: Ask for examples of past work. This provides insight into their expertise. Don’t hesitate to request references from previous clients. Their feedback can reveal a lot about reliability.

Consider the company's certifications. This indicates their commitment to quality standards. A company with ISO certifications is likely to follow strict protocols. However, not all experienced companies have formal certifications, which can make it tricky.

Tips: Look for customer reviews online. They can expose potential red flags. Every company has imperfections; acknowledging them can save you time and money. Take a proactive approach to understand their weaknesses. It helps in making an informed decision about your needs.

2026 How to Choose the Right PCB Company for Your Needs?

| Capability Dimension | Rating (1-5) | Comments |

|---|---|---|

| Manufacturing Technology | 4 | Advanced machinery and techniques implemented |

| Quality Control | 5 | Rigorous testing and inspection procedures |

| Customer Support | 4 | Responsive and knowledgeable support team |

| Turnaround Time | 3 | Standard delivery times, no rush options |

| Design Services | 5 | Offers comprehensive design support and simulation tools |

| Cost Competitiveness | 3 | Prices are generally on par with industry norms |

| Product Range | 4 | Wide variety of PCB types, including flexible and rigid |

Comparing Pricing Structures and Cost Factors in PCB Manufacturing

When choosing a PCB manufacturer, understanding pricing structures is crucial. Many companies use different models. Some charge per unit, while others use a tiered pricing strategy. This can make comparison challenging. Look closely at what is included in the quoted prices. Some might offer free shipping, while others might add unexpected fees. Clarifying these details is essential before making any decisions.

Cost factors vary greatly depending on the complexity of designs and materials used. Simpler designs often cost less, but intricate boards lead to increased expenses. If you’re working with limited funds, be aware. Overspending on high-end materials may not be necessary for basic projects. It’s also vital to consider production volume. Bulk orders reduce per-unit costs, but they require upfront investment.

Every manufacturer has strengths and weaknesses. Some may excel at quick turnaround times. Others may focus on quality. Finding the right balance for your project is key. Don’t hesitate to ask for quotes and clarify any uncertainties. Gathering multiple opinions can help. It’s important to perform due diligence. Understanding pricing in PCB manufacturing can empower you to make informed choices.

Comparison of PCB Manufacturing Costs

Assessing Quality Standards and Certifications in PCB Production

When selecting a PCB manufacturer, understanding quality standards and certifications is vital. The industry often refers to IPC standards. These standards help ensure consistent quality. IPC-A-600 covers the acceptability of printed boards. More than 50% of manufacturers adhere to this standard, reflecting its importance.

Certifications like ISO 9001 also play a crucial role. This certification signifies streamlined processes and quality management systems. According to a recent report, companies with ISO 9001 certification experience a 20% reduction in manufacturing defects. However, not all manufacturers prioritize earning such credentials.

It’s essential to assess how a company maintains its quality. Some businesses may boast certifications yet fail to implement the practices effectively. Also, consider their testing methods for solder joints and materials. A study showed that nearly 30% of PCB failures stem from inadequate testing practices. It's crucial to dig deeper and get clarification on their processes. Don't settle for surface-level assurances.

Reviewing Customer Support and After-Sales Services from PCB Suppliers

When selecting a PCB supplier, customer support and after-sales services are crucial.

A recent study indicated that 70% of customers prioritized effective communication when dealing with suppliers.

A responsive support team can resolve issues quickly, ensuring minimal production downtime. Companies should consider suppliers that provide multiple channels for contact, including phone support, email assistance, and live chat options.

After-sales services also play a significant role in overall satisfaction. According to industry reports, about 60% of users reported dissatisfaction due to inadequate follow-up after delivery.

It’s vital to evaluate if the PCB supplier offers warranty services, repair options, and troubleshooting assistance.

Moreover, clear documentation and user manuals can significantly enhance the post-purchase experience.

Some PCB companies may lack comprehensive support frameworks, leaving customers frustrated. It’s essential to inquire about the specific support available.

Do they have a dedicated team for technical inquiries? Are there resources for self-service troubleshooting?

Customers should seek clarity on these points. Only then can they ensure a smoother relationship with their chosen PCB supplier.

Related Posts

-

Top PCB Companies of 2025: What to Look for in Quality and Innovation?

-

Unlocking the Mysteries of Motor Control: How Your Brain Powers Movement

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

10 Essential Tips for Understanding Motors and Control Systems Effectively

-

Top 10 Motion Solutions for Streamlined Business Operations

-

How to Choose the Right Motor Control Solutions for Your Industrial Needs