How to Choose the Best Linear Motion System for Your Application

Choosing the right linear motion system can greatly impact the efficiency of your operations. Industry expert Dr. Sarah Thompson, a leading figure in motion control technology, emphasizes, "Selecting the proper linear motion system is crucial for achieving optimal performance." Her words remind us that this decision should not be taken lightly.

When evaluating a linear motion system, consider the specific requirements of your application. Load capacity, speed, and precision are essential factors. Many companies overlook these details, leading to suboptimal solutions. For example, a compact design may seem appealing, but it could compromise load-bearing capacity and durability.

Investing time in understanding the nuances of different systems is vital. Collaborate with experts and gather insights. Remember, even minor miscalculations can lead to major issues later. Take the time to reflect on what you truly need. In the world of linear motion systems, the stakes are high.

Understanding Linear Motion Systems and Their Applications

Linear motion systems play a critical role in various industries. They enable smooth movement and precise positioning of components. From factory automation to robotics, these systems are essential. A simple example is a conveyor belt, which moves products seamlessly across a production line.

Understanding the different types of linear motion systems is vital for effective application. There are belt-driven systems, screw-driven systems, and more. Each has unique benefits and limitations. For instance, a belt-driven system can be faster but may lack precision in positioning. In contrast, screw-driven systems offer better accuracy but can operate slower.

Choosing the right system requires careful consideration. Think about the specific needs of your application. Will speed or precision be a priority? It can be tricky to find the perfect match. Testing different systems could lead to unexpected insights. Engaging with a technician can help clarify doubts. Don't hesitate to iterate and refine your choice. Each application is distinct and may need adjustments.

Key Factors to Consider When Selecting a Linear Motion System

Selecting the right linear motion system can be challenging. There are key factors to consider. Start with load capacity. How much weight will the system carry? Exceeding the limit can cause failure. Consider the speed requirements as well. Different applications need different speeds. Is it for a fast assembly line or a slow precision task?

Another important aspect is precision. How accurate does the positioning need to be? Applications in robotics often require tight tolerances. Don’t overlook the environment either. Dusty or wet conditions can affect system performance. Material selection can greatly impact durability and maintenance needs.

Finally, think about assembly and integration. Will it fit into your existing setup? A system that is difficult to install can waste time and money. It's crucial to reflect on these factors. A misstep can lead to costly errors. Balancing your specific needs with available options is essential for success.

Linear Motion System Selection Factors

This bar chart illustrates the key factors to consider when choosing a linear motion system, rated on a scale of importance from 1 to 10. Factors such as load capacity, speed, and accuracy are crucial in making an informed decision for your application.

Types of Linear Motion Systems and Their Benefits

There are various types of linear motion systems available today. Each type offers distinct benefits tailored to specific applications. For instance, ball screw systems are efficient for precision tasks. They provide minimal friction and high load capacity. According to a recent industry report, these systems can achieve up to 90% efficiency in converting rotary motion into linear motion.

On the other hand, linear actuators are popular for automation. They are easy to control and integrate into existing systems. Many industries prefer these for their reliability. However, they may not provide the same precision as ball screws. A study shows that linear actuators often have a backlash issue, which can diminish accuracy.

Additionally, belt-driven systems are favored for speed. They excel in high-speed applications but may sacrifice precision. Their performance can vary based on the application’s demands. It’s important to reflect on the specific requirements when choosing a system. Each type has its pros and cons, making it crucial to assess what best suits your operational needs.

Evaluating Performance Specifications for Linear Motion Systems

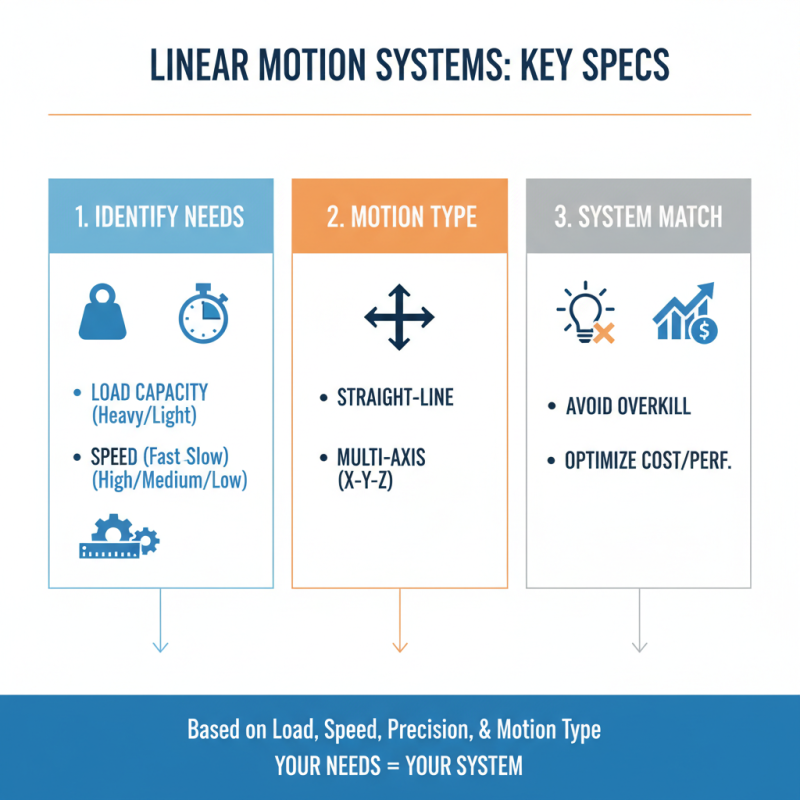

When evaluating performance specifications for linear motion systems, the first step is to identify your specific needs. Consider load capacity, speed, and precision. A system designed for heavy loads may be overkill for lighter tasks. Think about the type of motion as well. Linear systems can provide straight-line motion, but some applications may benefit from multi-axis capability.

Another critical factor is environment. Some systems operate well in harsh conditions, while others do not. Dust, moisture, and temperature can all impact performance. If your application is in a factory, durability matters. Regularly assess how external factors might affect longevity. This reflection can lead to better decision-making.

Finally, don’t forget maintenance. Specifications should highlight ease of upkeep. Systems requiring specialized maintenance might lead you to frustration down the line. Assessing these details can save money and time. Choosing the right linear motion system is about more than just specifications; it's also about compatibility with your operational needs.

Cost vs. Quality: Making the Right Choice for Your Needs

In the world of linear motion systems, the balance between cost and quality often creates a dilemma. Recent industry reports indicate that nearly 70% of manufacturers prioritize budget constraints over the durability and efficiency of their systems. Choosing a cheaper option may lead to increased maintenance costs and unscheduled downtime. For example, systems that are 20% cheaper may require repairs twice as often, impacting overall productivity.

Investing in a quality linear motion system can pay off in the long run. Data shows that high-quality systems can improve efficiency by up to 30%. This translates to better output and less waste. However, discerning the right quality often requires critical analysis. Some users end up overestimating their needs, leading to unnecessary expenditures on features that may never be used.

It’s essential to consider application-specific requirements. The right system should match the load capacity and speed needed for your operations. Too often, companies choose a system without adequate analysis, only to find it doesn't sync with their processes. Balancing cost and quality isn’t straightforward, and each decision must be made with caution.

How to Choose the Best Linear Motion System for Your Application - Cost vs. Quality: Making the Right Choice for Your Needs

| Criteria | Low-Cost Systems | Mid-Range Systems | High-Quality Systems |

|---|---|---|---|

| Initial Cost | $100 - $500 | $500 - $1500 | $1500 - $5000 |

| Lifespan | 1 - 2 years | 3 - 5 years | 5+ years |

| Load Capacity | 5 - 50 kg | 50 - 200 kg | 200+ kg |

| Speed | 0.5 - 1 m/s | 1 - 3 m/s | 3 - 6 m/s |

| Precision | ±0.1 mm | ±0.05 mm | ±0.01 mm |

| Maintenance Needs | Frequent | Moderate | Minimal |

Related Posts

-

10 Essential Tips for Choosing the Right Motion Control Systems

-

10 Essential Tips for Understanding Motors and Control Systems Effectively

-

Exploring the Science Behind Etel Motion and Its Impact on Modern Technology

-

2025 How to Select the Right Motors and Control Systems for Your Project

-

The Future of Automation with Etel Linear Motors What You Need to Know

-

10 Best Etel Motors Models You Need to Know for 2024