2025 How to Choose the Best Motion Control Motors for Your Applications

The demand for motion control motors is surging across various industries, driven by the increasing need for automation and precision in manufacturing processes. According to a report by MarketsandMarkets, the global motion control market is projected to reach USD 23.56 billion by 2025, growing at a CAGR of 8.4% from 2020 to 2025. This growth highlights the critical importance of selecting the right motion control motors tailored to specific applications, ensuring efficiency, productivity, and cost management.

Industry experts emphasize the intricacies involved in choosing the most suitable motion control motors. Dr. Emily Zhang, a leading expert in the field of robotics and automation, states, “The right motion control motor can not only enhance operational performance but also significantly reduce maintenance costs and downtime." With the variety of options available, ranging from stepper motors to servo motors and brushless DC motors, it becomes essential to understand the unique characteristics and performance parameters associated with each type.

In conclusion, making informed decisions when selecting motion control motors is crucial for optimizing application performance. As industries continue to advance towards greater automation, understanding the specific requirements of your application along with the attributes of different motor types will be vital for success in a competitive landscape.

Understanding Motion Control Motors: Types and Applications

Understanding motion control motors is essential for selecting the right type to suit your specific application. Motion control motors can be broadly categorized into three main types: stepper motors, servo motors, and DC motors. Each of these types has distinct characteristics that make them suitable for different tasks. Stepper motors are ideal for applications requiring precise position control, as they move in discrete steps, enabling accurate control of angular position. This makes them a popular choice in 3D printers and CNC machines.

On the other hand, servo motors are preferred for their ability to provide high torque and velocity control. They often integrate feedback systems, allowing for enhanced performance in applications like robotics and automated machinery, where constant monitoring and adjustment are crucial. Meanwhile, DC motors are commonly used in simpler applications where speed control and efficiency are key, such as in fans or pumps. Understanding these distinctions can significantly impact the performance and effectiveness of the end application, making it vital to analyze the specific requirements before making a decision on the motor type.

Key Factors in Selecting Motion Control Motors for Your Needs

When selecting motion control motors for your applications, several key factors should guide your decision-making process. Firstly, it's essential to understand the specific requirements of your project, such as speed, torque, and precision. Different applications have distinct needs—robotics may demand high precision and quick response, while conveyors might prioritize torque and durability. By clearly defining your application's specs, you can narrow down the types of motors that will best suit your requirements.

Another critical consideration is the operating environment. Factors such as temperature fluctuations, potential dust or moisture exposure, and space limitations can significantly influence the performance and lifespan of motion control motors. Selecting motors designed for harsh conditions can ensure reliability and efficiency. Additionally, evaluating the control system compatibility and the ease of integration within your current framework is vital. An ideal motor should seamlessly work alongside existing equipment while allowing for future scalability as your needs evolve.

Evaluating Performance Specifications of Motion Control Motors

When selecting the best motion control motors for specific applications, evaluating their performance specifications is crucial. Key performance metrics include torque, speed, and accuracy, all of which play a significant role in how effectively a motor meets the demands of a project. Torque determines the motor's ability to handle loads, while speed affects the response time and efficiency of the system. It’s also vital to assess the type of motion required—linear or rotational—as this influences the choice of motor type.

Another important consideration is the motor's operating environment. Factors such as temperature range, humidity, and exposure to dust or moisture can impact the motor's performance and longevity. Additionally, examining the power requirements and compatibility with existing control systems can streamline integration and enhance reliability. Finally, understanding the duty cycle and how the motor will be utilized over time will help in selecting a motor that can sustain performance without overheating or experiencing premature wear. By thoroughly evaluating these specifications, one can ensure that the motion control motor functions optimally within its intended application.

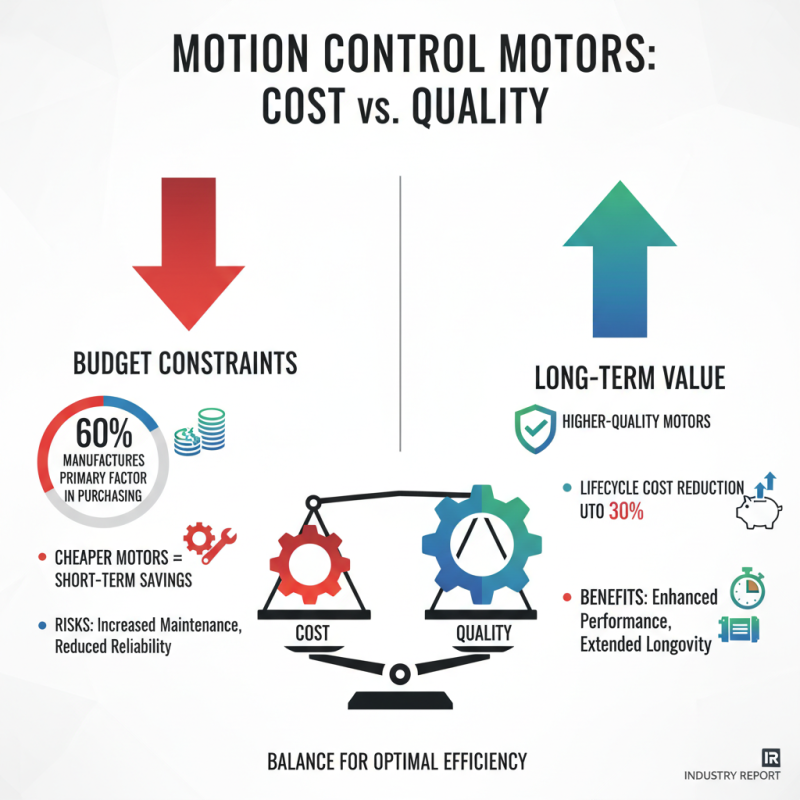

Comparing Cost vs. Quality in Motion Control Motors

When it comes to selecting motion control motors for various applications, the balance between cost and quality is often a critical consideration. According to a recent industry report, around 60% of manufacturers cite budget constraints as the primary factor influencing their purchasing decisions. However, opting for cheaper motors can lead to long-term inefficiencies, including increased maintenance costs and reduced reliability. In some cases, investing in higher-quality motors can result in a lifecycle cost reduction of up to 30% due to their enhanced performance and longevity.

Quality motion control motors are typically engineered using superior materials and manufacturing processes, which contribute to their durability and efficiency. For instance, motors rated for higher power density and extended operational life can initially appear more expensive, but data indicates that they can deliver anywhere from 2 to 5 times the service life of lower-cost alternatives. This performance advantage is crucial in applications that require precision and reliability, such as robotics and automated manufacturing systems. Thus, while the upfront investment may be greater, the payoffs in terms of operational efficiency and reduced downtime can make quality motors a more economical choice over time.

Future Trends in Motion Control Motor Technologies for 2025

As we look toward 2025, the motion control motor industry is poised for significant advancements driven by emerging technologies and evolving application demands. One of the most notable trends is the increased integration of artificial intelligence and machine learning into motion control systems. These technologies enable smarter and more adaptive motor controls, allowing for real-time adjustments based on operational conditions. This shift not only enhances performance but also improves energy efficiency, catering to industries that prioritize sustainability within their processes.

Another important trend is the miniaturization of motion control motors. With the growing need for compact and lightweight solutions in applications such as robotics and portable devices, manufacturers are focusing on developing smaller yet powerful motor designs. This trend is supported by advancements in materials, such as high-strength magnetic components and innovative manufacturing techniques, which contribute to improved performance without compromising on size. As these trends converge, the motion control motor landscape will redefine operational capabilities, making it essential for businesses to adapt to stay competitive in an increasingly automated world.

Related Posts

-

Unlocking the Power of Etel Motion for Enhanced Digital Experiences

-

Exploring the Future of Motor Control Solutions: Innovations That Drive Efficiency and Precision

-

2025 Top 10 Innovations in Motors and Control Systems You Must Know

-

Why Motion Control Systems Are Essential for Modern Automation Solutions

-

10 Essential Tips for Choosing the Right Motion Control Systems

-

10 Best Etel Motion Products for Ultimate Comfort and Style in 2023